Software solutions for precise measurement and meaningful analysis

Modern 3D surface metrology requires powerful software—both for precise control of measurement systems and detailed analysis of captured data. Our software solutions provide the perfect link between hardware, user-friendliness, and analytical depth.

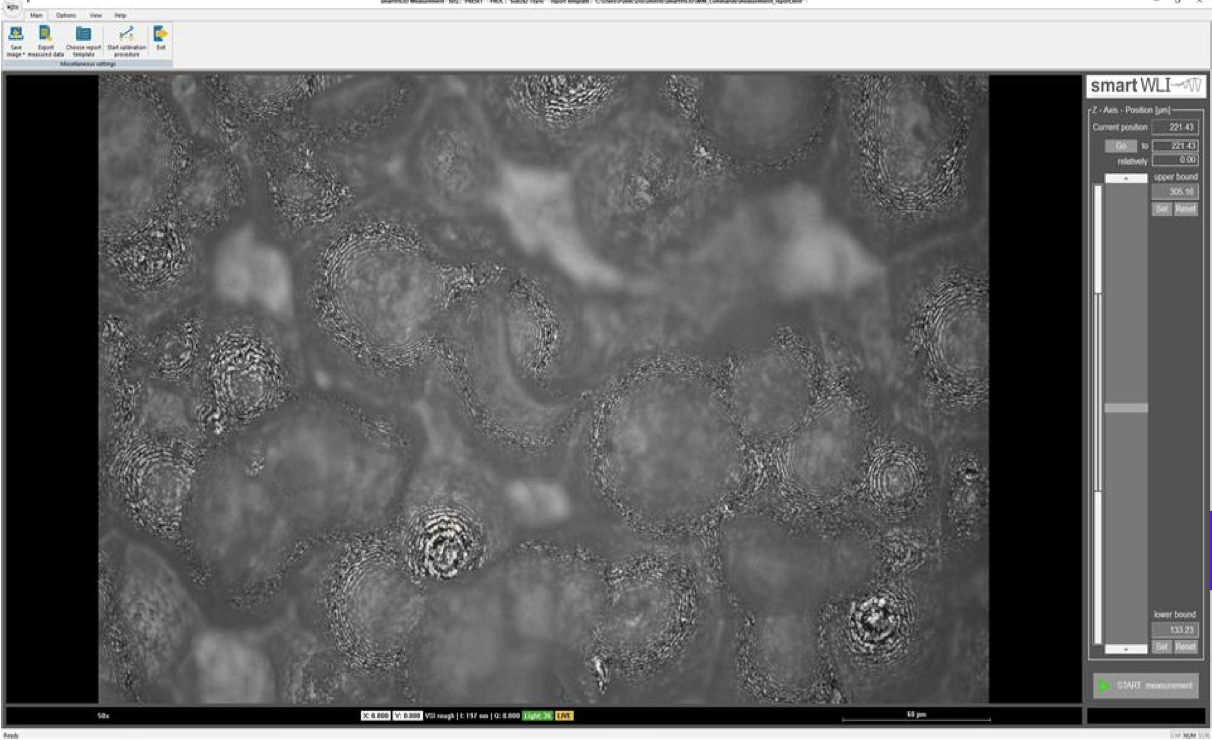

With our measurement software, you control the device intuitively, precisely, and reproducibly—from positioning the sample and selecting measurement parameters to automated data acquisition.

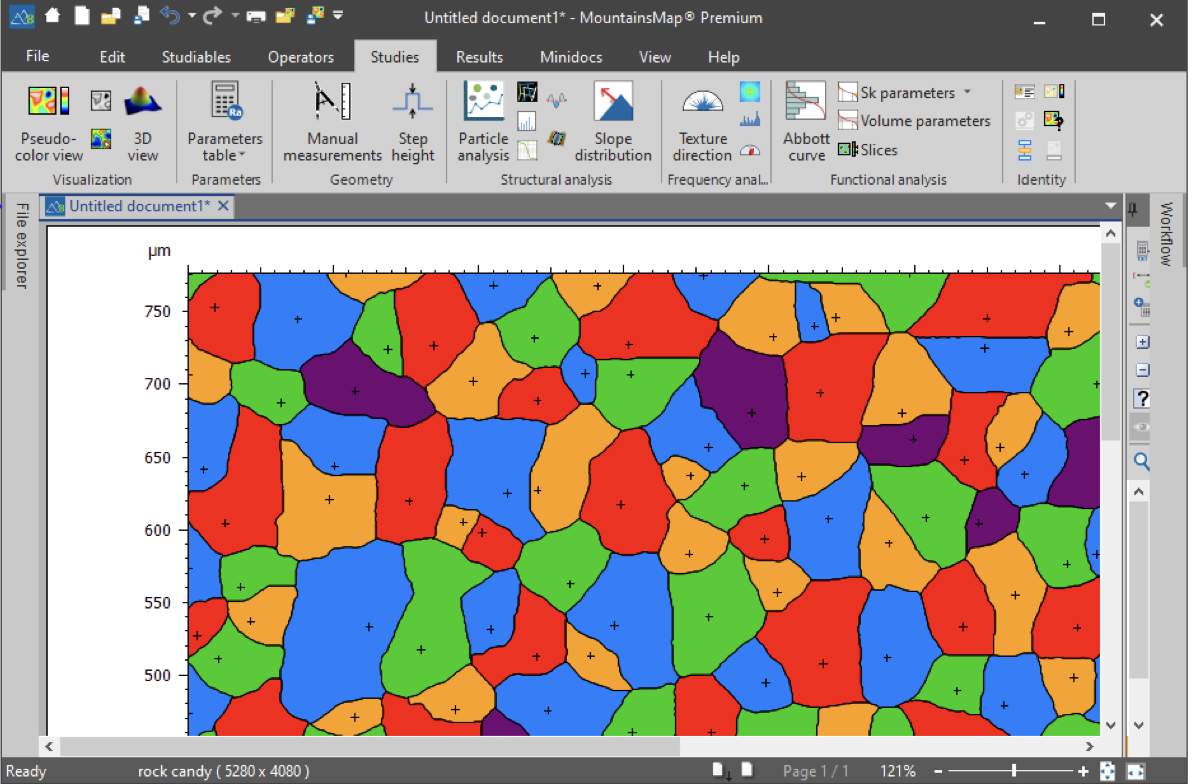

For subsequent analysis, we rely on the powerful evaluation software MountainsMap®. It offers a comprehensive range of tools for 3D visualization, structural analysis, roughness evaluation, form inspection, and more—standards-compliant, transparent, and visually compelling.

Whether simple standard evaluation or complex surface analysis: our software solutions help you obtain reliable and interpretable results from your measurement data.

Precise 3D Surface Metrology for Every Application

Our optical measurement solutions cover the entire spectrum of 3D surface analysis – from highly precise instruments for laboratories and research to robust systems for production and integration, as well as custom-developed special solutions. Whether micro- and nanostructures or roughness measurements, you receive the optimal non-contact metrology for every application area – reliable, flexible, and tailored precisely to your requirements.

Measuring Instruments for Laboratory & Research Applications

Our measuring instruments for laboratory and research are specially designed for the highest precision and flexibility. They enable detailed analyses of micro- and nanostructures and provide reliable measurement results for demanding research and development projects. With state-of-the-art white light interferometry and innovative image processing, these systems offer ideal conditions for scientific applications and technical quality management.

Measuring Instruments for Production & Integration Applications

Designed for use in production and directly within manufacturing processes, our measuring instruments stand out for their robustness, short measurement times, and easy integration into existing production lines. They support efficient quality assurance with fast, non-contact measurements—both inline and near-line—and are specifically tailored to the demands of industrial applications.

Custom solutions

Every product is only as good as its fit – that’s why we develop individual, custom metrology solutions precisely tailored to your requirements and processes. Whether special designs, modifications of existing systems, or complex measurement stations – our experienced team supports you from conception to commissioning and beyond.

Why GBS?

We measure, analyze, and visualize technical surfaces in 3D – from tool steel to semiconductor wafers. Precise. Comparable. Reproducible.

Years of Market Experience

Industry Partner

Made in Germany

Installed Systems in the Last 5 Years

Our advantages

GBS metrology GmbH offers advanced optical 3D metrology that perfectly combines precision, reliability, and efficiency. Our non-contact systems for roughness, microstructure, and nanostructure measurements deliver reproducible results, save testing time, and can be flexibly adapted to your individual requirements—ideal for research, development, and modern manufacturing.

In-house product development

Minimal maintenance required

Full automation possible

Faster ROI of products

First-hand support

Short measurement times – real-time evaluation on GPGPUs