smartVIS3D – system software

With smartVIS3D, you experience the perfect combination of state-of-the-art 3D surface measurement technology and powerful software. The system software enables intuitive handling, real-time processing of high-resolution 3D data, and efficient control of your measurement device – for reproducible and reliable results.

| graphical user interface | |

| visualization | camera image, intensity adjustment, contrast enhancement |

| parameter control | scanning range, increments, evaluation macros, ROI, decimation |

| Resolution | High-resolution 3D data |

| evaluation algorithms | |

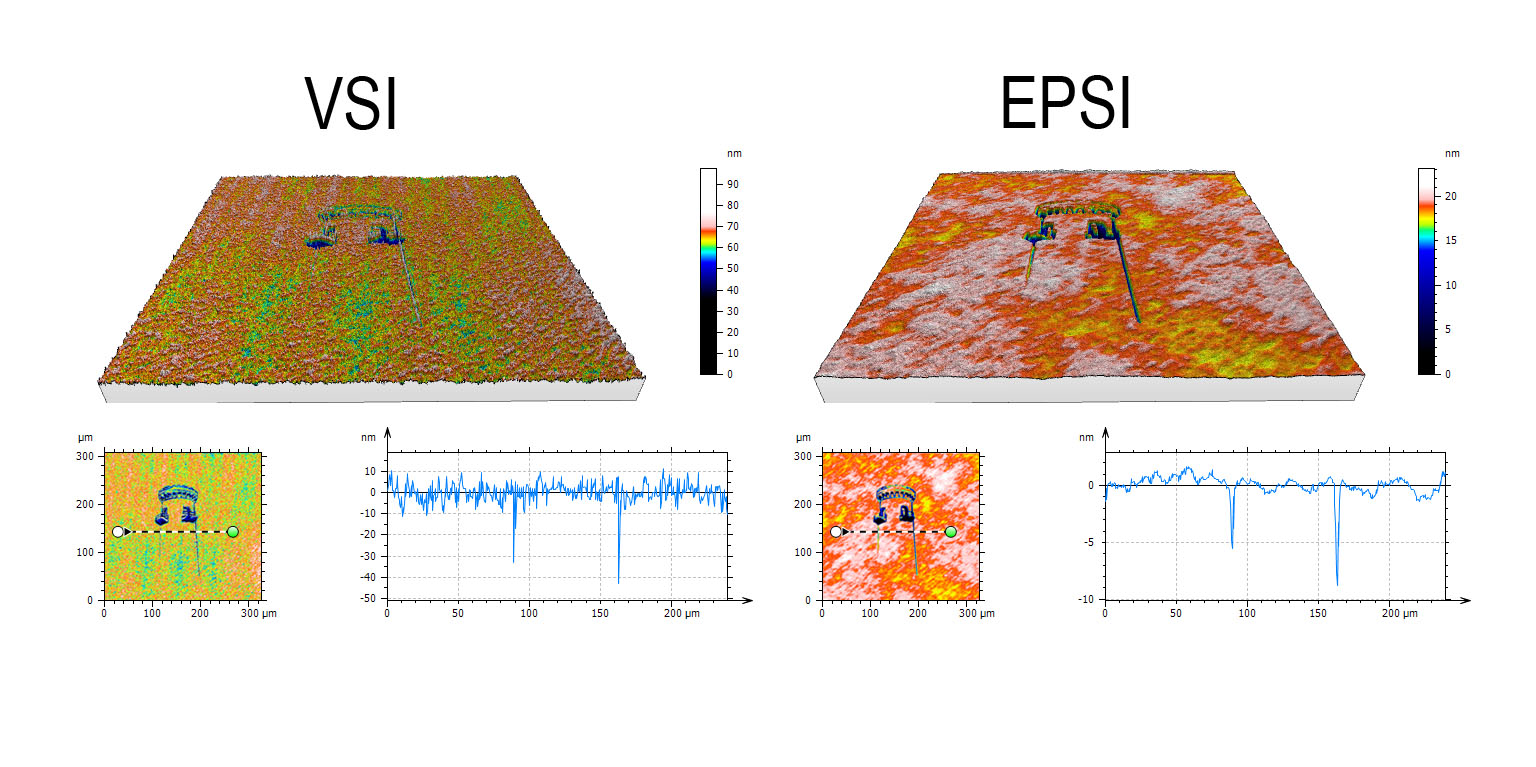

| VSI | vertical scanning interferometry |

| EPSI | extended phase shift interferometry |

| GPGPU | real time evaluation of 3d data on programable graphic boards |

| infinite focus | optional generation of an infinite focus camera layer elimination of interference fringes |

| data quality surveillance | |

| functionality | use and exports optional data quality information based on correspondence of the registered signal with an ideal interference signal (correlogram) for each measuring point all 3d point undergo an additional plausibility check |

| control of motorized stages | |

| positioning | movement control |

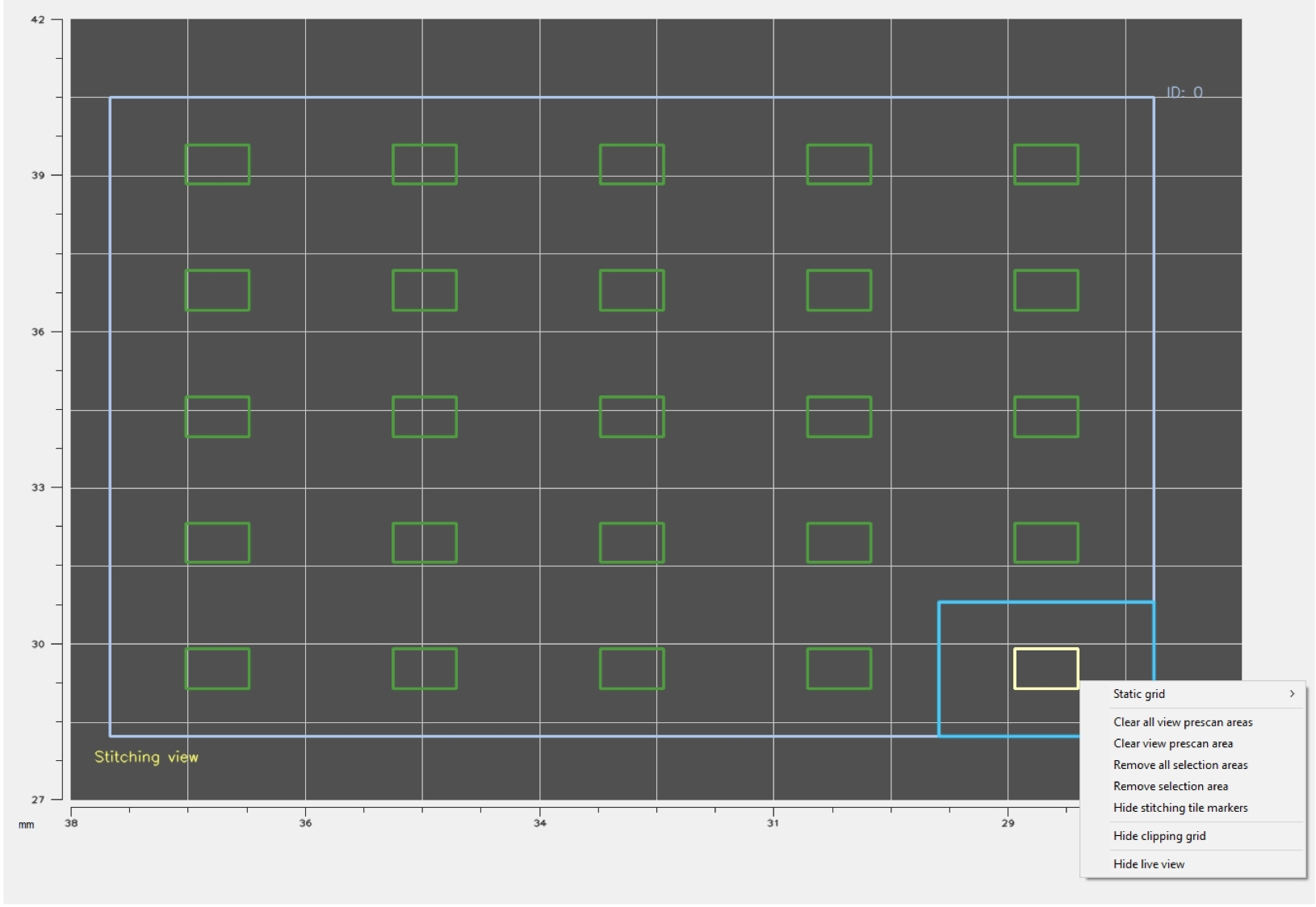

| stitching | macro generation for multiple scans and stitching automated measurements of multiple positions or stitching areas |

Intuitive control and automated workflows

With smartVIS3D, you control the measurement system effortlessly – from sample positioning to data acquisition:

-

Selection of the measurement volume in X, Y, and Z

-

Configuration of measurement parameters such as objective, illumination, and speed

-

Support for EPSI/VSI for highest Z-resolution

-

Selection of evaluation scope via MountainsMap macros

smartVIS3D is ideally suited for:

-

High-precision surface measurements in research and development

-

Quality assurance in the production of lenses, glass, and microstructures

-

Analysis of steep, transparent, or rough surfaces

High-speed measurements with maximum precision

smartVIS3D delivers massive computing power with over 80 TFLOPS across more than 16,000 cores, enabling real-time processing of high-resolution 3D data.

-

Up to 8 million data points per capture

-

Up to 3,000 images per second

-

Vertical scanning speeds of up to 400 µm/s

-

Up to 75,000 images per measurement

-

Supports up to 450 GB of image data

Thanks to real-time GPU-based processing, you receive 3D data without delay – even for complex and steeply inclined surfaces.

Intelligent image processing

for precise results

Our software offers advanced algorithms for image correction, contrast optimization, and flexible measurement control—developed for maximum measurement accuracy even with challenging samples:

- Customizable measurement range for individual requirements

- Reliable measurement of transparent and steeply inclined surfaces

- Smooth, artifact-free edges thanks to model-based signal processing

- Automatic outlier detection for maximum lateral resolution

- Dynamic lighting and contrast adjustment for easy positioning and reliable detection

- Selective removal of unwanted scan areas

Highest height resolution with Extended Phase-Shift Interferometry (EPSI)

For applications requiring maximum precision, our system with Extended Phase-Shift Interferometry (EPSI) offers Z resolution in the sub-nanometer range – ideal for extremely smooth and optically polished surfaces.

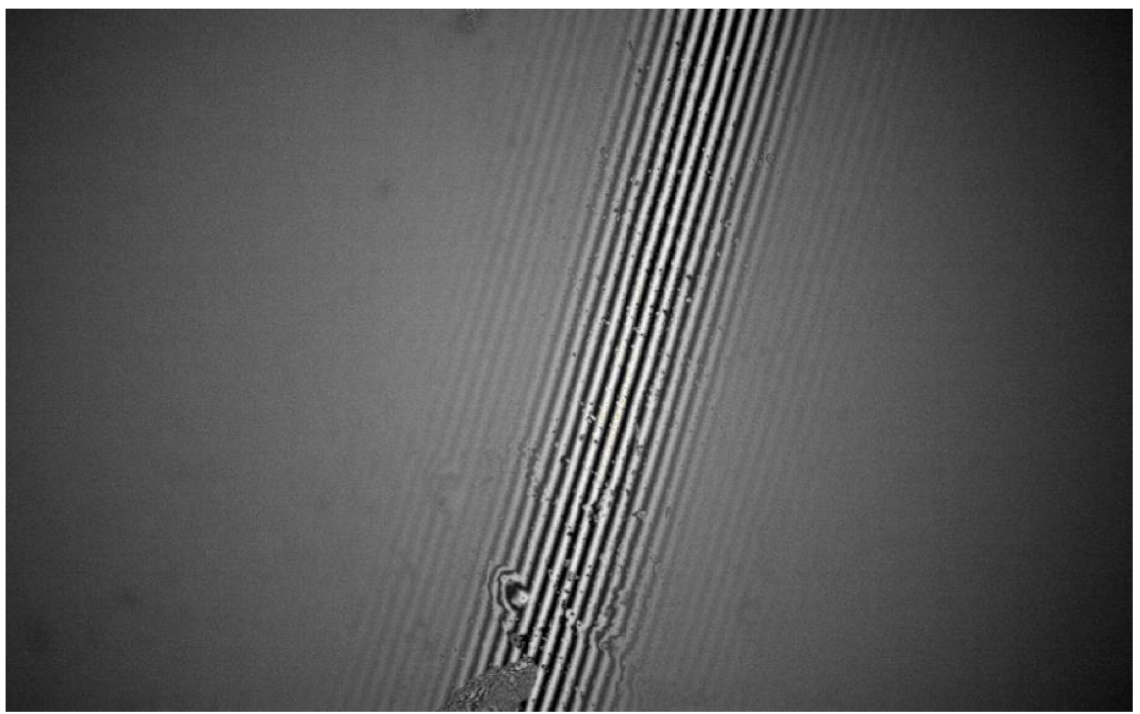

EPSI uses precise phase evaluation within the interference signals and extends classic methods with finely tuned phase shifts at a high vertical sampling rate. In combination with model-based signal processing and GPU-accelerated evaluation, EPSI enables reliable detection of the finest height differences – even with minimal contrast or weak reflection

Your advantages:

- Sub-nanometer Z resolution for ultra-precise surface analysis

- Optimized for reflective, smooth, and functionally coated materials

- Stable against environmental noise thanks to highly dynamic signal evaluation

- Ideal for applications in optics, semiconductor manufacturing, micromechanics, and research

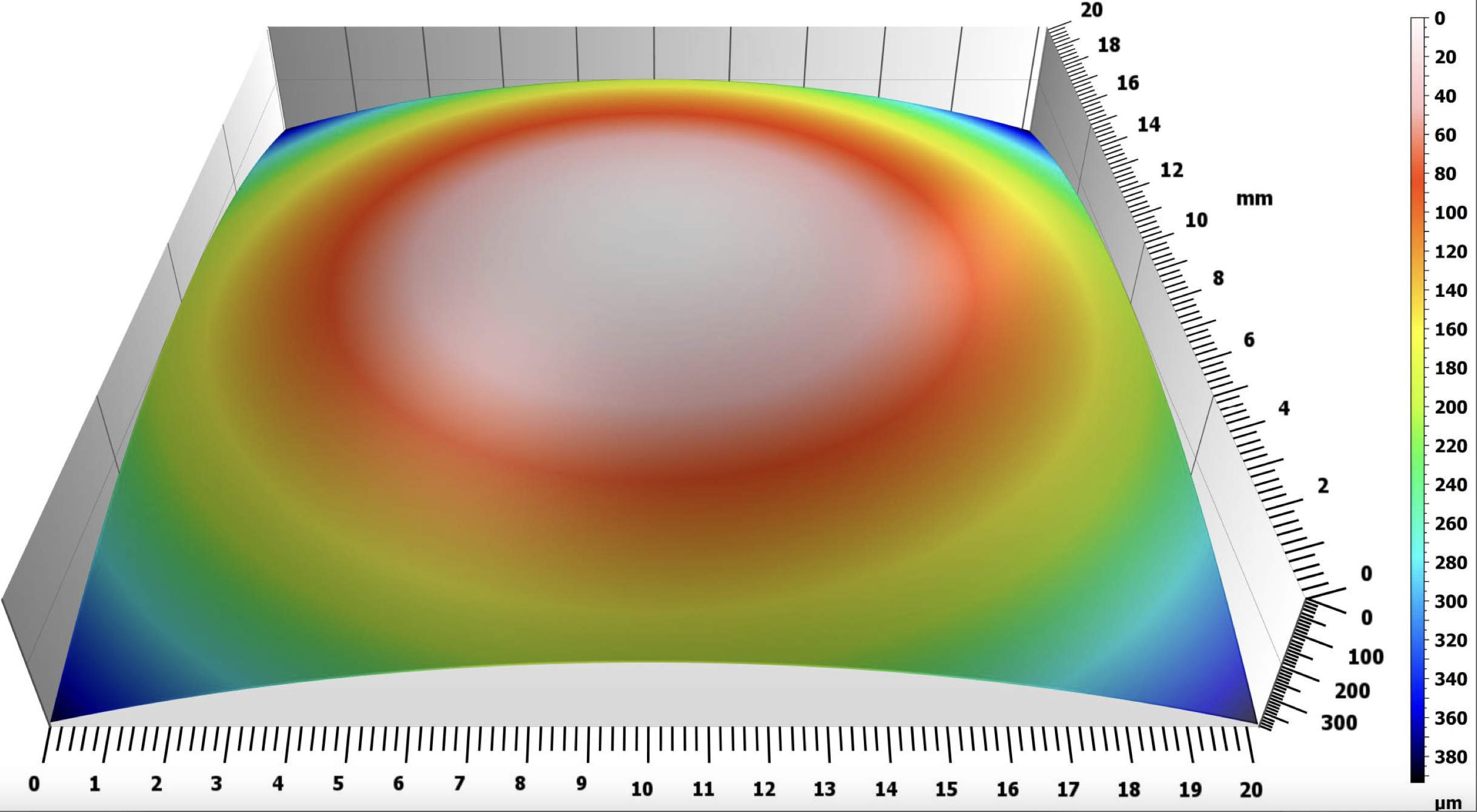

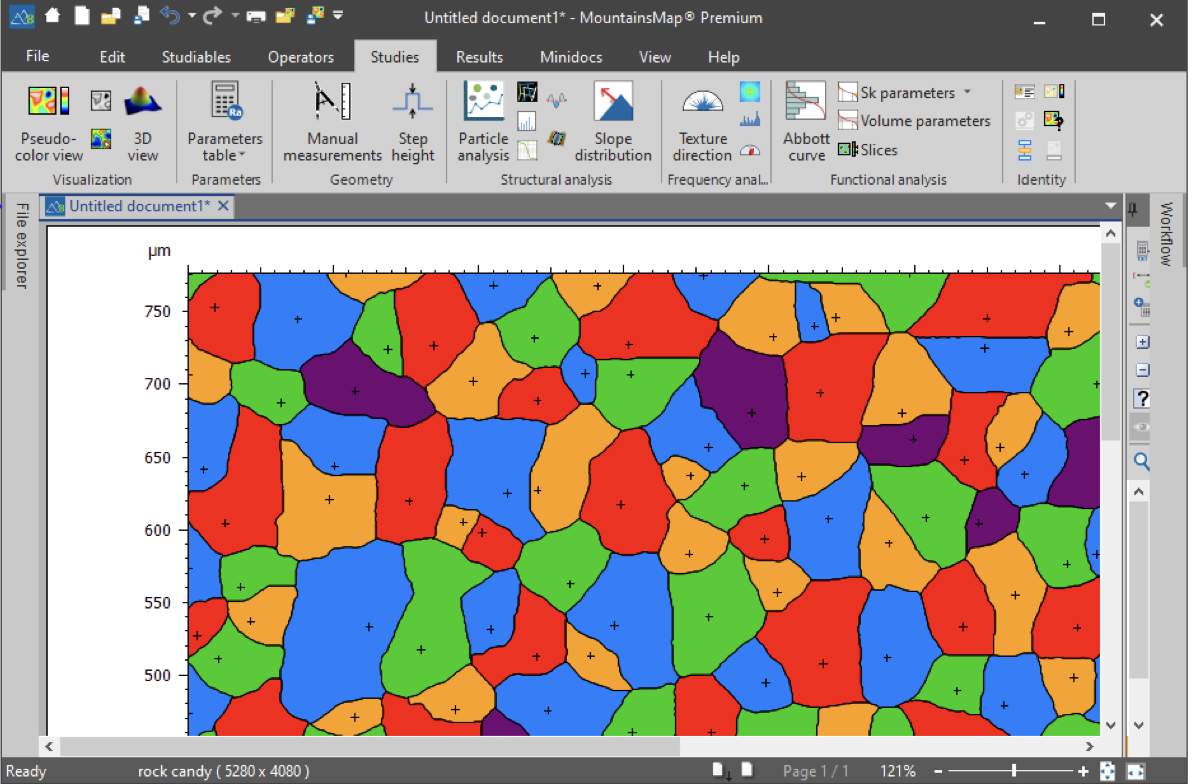

Powerful data analysis with MountainsMap®

For precise and user-friendly evaluation of your 3D measurement data, smartVIS3D is fully integrated into the MountainsMap® analysis platform—the globally established software solution for surface metrology.

The seamless connection enables direct further processing of interferometry measurements from smartVIS3D—from visualization to in-depth analysis.

Your analysis advantages with MountainsMap®:

- Intuitive 3D visualization of surface structures and profile sections

- Roughness and waviness evaluation according to international standards (ISO, DIN, JIS, etc.)

- Form inspection and statistical structural analysis of complex functional surfaces

- Tolerance comparisons with user-defined or standard-based limit values

- Automated evaluation of large measurement series via macros and batch processing

- Data export in numerous formats for documentation, further processing, or reporting (e.g., PDF, Excel, CAD)

Customizable and powerful: Whether for research, quality assurance, or series testing, MountainsMap® is the ideal complement to smartVIS3D for all applications where surface function matters.

smartVIS3D DLL for integrators

| functionality | library to control all sensor functions from a third-party software in contrary to the standard smartVIS3D is no GUI included |

| programming languages | C++; C# |

| documentation | handbook source code of an example application for instant success and test of sensor functions |

Flexible software upgrades for smartVIS3D

Expand your smartVIS3D software with powerful upgrade modules tailored to your specific applications in quality assurance, production monitoring, or research and development. The modular extensions enable maximum functionality and precision – exactly when you need them.

Overview of available upgrade modules:

- Extension Project Management

Automation of complex measurement projects with multiple measurement positions, automatic focus, lens change, and optional leveling—ideal for time-consuming applications such as wafer measurements or structured substrates. - HD-EPSI / High Precision

For high-precision height measurements in the sub-nanometer range – ideal for reflective, smooth, or optically polished surfaces, e.g., in semiconductor, optical, or medical technology. - smartStitch

Seamless stitching of multiple individual measurements into large-area, high-resolution 3D data sets – e.g., for wafers, tool inserts, or structured surfaces in the µm range. - smartLayer

Layer-by-layer analysis and visualization of complex multilayer structures – ideal for transparent layers, coatings, or microstructured components. - IO-Module Package

Integrate smartVIS3D into automated measurement systems – with digital inputs/outputs, trigger functions, and flexible interfaces for your production environment.

Scalable. Future-proof. Tailored to your requirements.

With the smartVIS3D software upgrades, you can upgrade your system in a targeted manner – expandable at any time, precisely adapted to your application.

HD-EPSI upgrade for smartVIS3D

| general description | the upgrade provides advanced functionality for noise reduction and acceleration of the data aquisition |

| prescan | dual scanning technology for fast surface and scanning range detection the prescan allows to scan a flats/ smooth with high resolution without losing time in a higher uncertainty range of the unknown surface position inside of the higher z scanning range |

| HD-EPSI | scanning with z-increments below λ/8 to acquire more information out of the interference zone for noise reduction |

| Profilmittelung | multiple scans including spike elimination and profile averaging in front of data forwarding to the evaluation software |

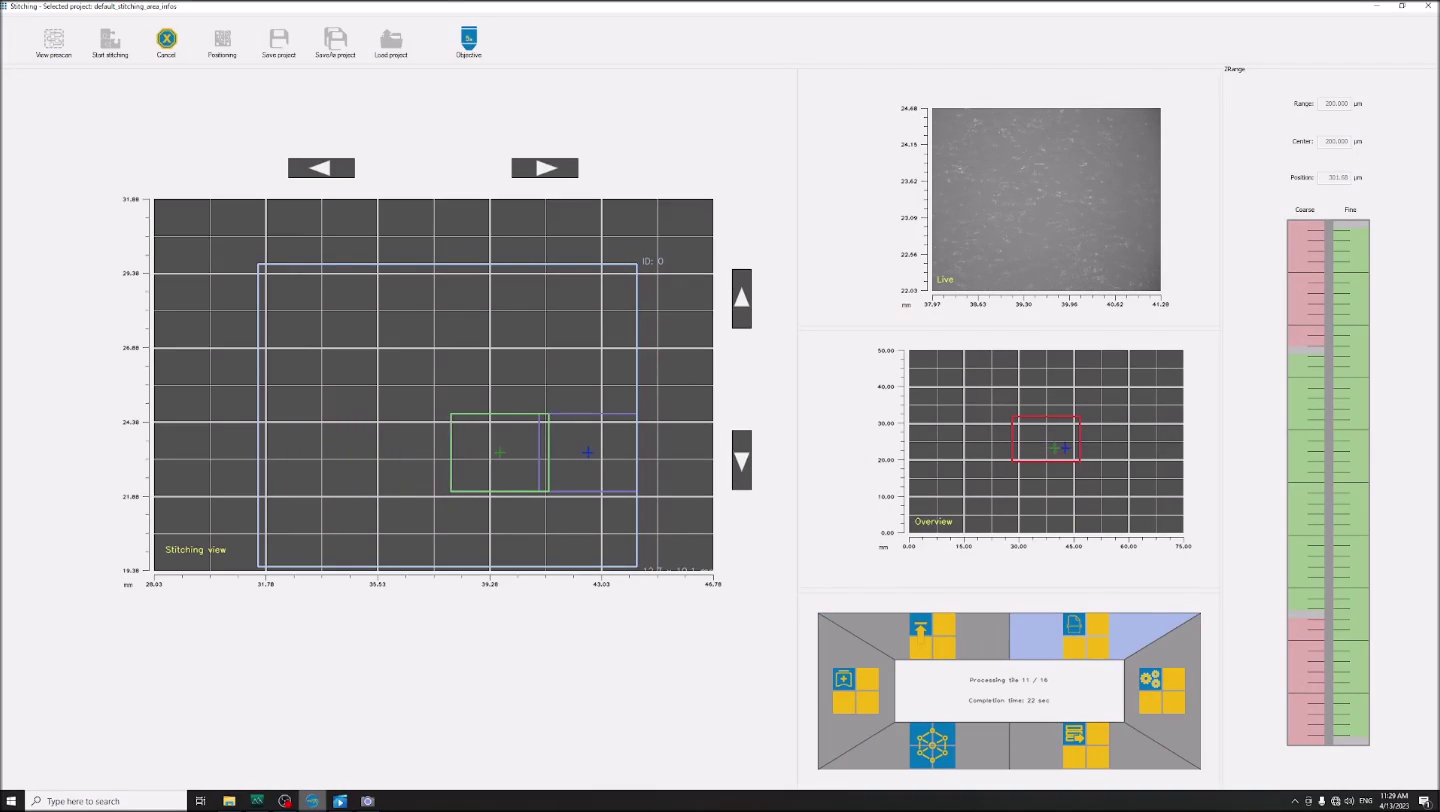

smartStitch upgrade for smartVIS3D

| functionality | the upgrade provides alternative (to the standard package MountainsMap®) algorithms to stitch 3d data together out of multiple single scans together the functions eliminate height and angular deviations based on overlapping areas and hand over stitched already stitched 3d data to the evaluation software |

smartLayer upgrade for smartVIS3D

| functionality | the upgrade can extract multiple layers from transparent samples once multiple correlograms are included in the scanning range |

smartVIS3D extension project management

| automation | generation of complex measuring tasks |

| measuring of multiple measuring positions | |

| automated result exports | |

| exchange of objective magnifications inside an automated workflow | |

| autofocus inside of the range of the motorized z-axis | |

| automatic leveling (restricted for hardware configuration including automated tip / tilt devices) / alternative interruptions for manual levelling | |

| hardware requirements | motorized xyz stages |

| sensors including an objective turret | |

| motorized tip/tilt recommended | |

| intention | providing an automated work for time consuming complex measuring task on wafers or similar flat samples |

smartVIS3D DLL Advanced

| prescan | dual scanning technology for fast surface and scanning range detection |

| HD-EPSI | scanning with z-increments below λ/8 to acquire more information out of the interference zone for noise reduction |

| he prescan allows to scan a flats/ smooth with high resolution without losing time in a higher uncertainty range of the unknown surface position inside of the higher z scanning range | |

| profile averaging | multiple scans including spike elimination and profile averaging in front of data forwarding to the evaluation software |

| client server architecture | library for remote control of the sensor control of the sensor from a third-party application run on another PC C++ |

IO Module

| functionality | sensor integration without programming and software expertise |

| triggering of predefined measuring and evaluation processes per IO signals | |

| Hardware | IO module USB Advantec USB-4750 |

| requirements | smartVIS3D evaluation software (MountainsMap® or alternative software packages) |