Calibration Standard for Flatness –

Planarity, flatness testing, surface calibration

Our flatness standards enable you to calibrate and test the planarity and flatness of your measuring systems to the highest standards. These standards are ideal for detecting and correcting system-related deviations and make a decisive contribution to increasing measuring accuracy across the entire measuring surface.

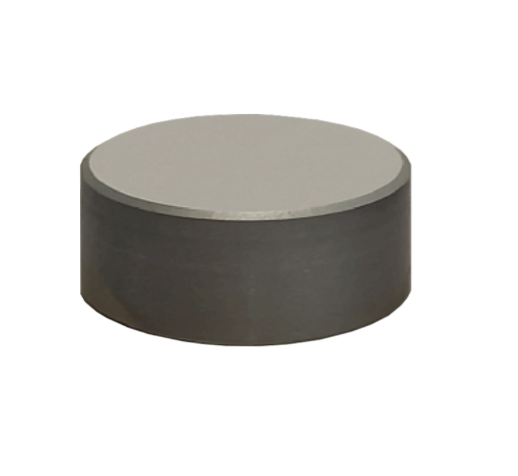

| TYP | Al surface mirror |

| Area of application | target for 2.5x – 115x objective |

| Diameter | 50 mm |

| Flatness | λ / 20 |

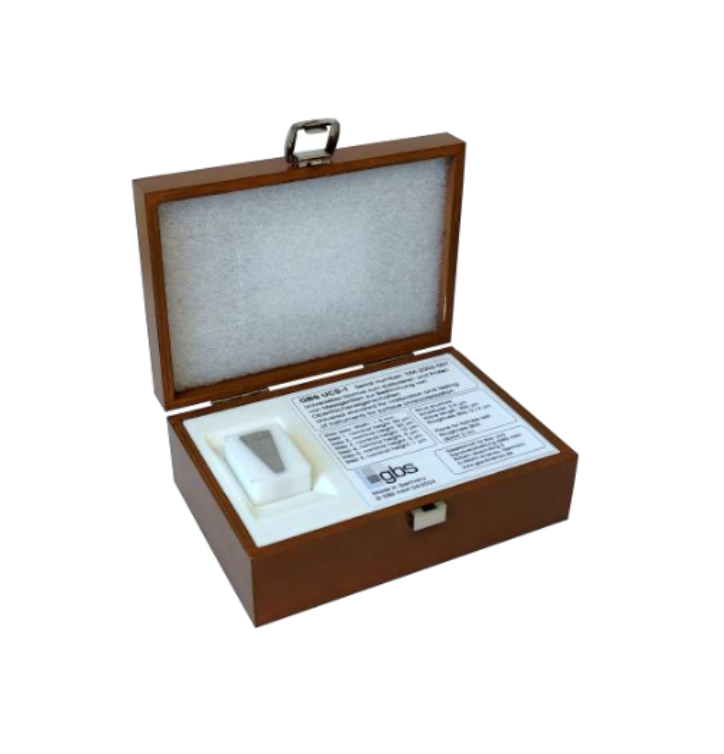

UCS-1 Universal Confirmation Standard

Other accessory categories

Maximum measurement accuracy requires not only a powerful 3D surface sensor, but also optimally matched accessories. Our range of accessories has been specifically developed to fully exploit the performance of our systems and take your measurement results to a new level.

Stands & granite portals

A reliable mechanical foundation is essential for high-precision measurement results. Our stands and granite portals offer maximum stability, vibration damping, and durability—ideal for use with 3D surface measurement systems in laboratory and production environments.

Objective lenses

Choosing the right lens is essential for the quality and significance of your measurement results. Our range includes specially designed lenses for different magnification ranges, working distances, and resolutions. This allows you to flexibly adapt your 3D measurement systems to a wide variety of requirements.

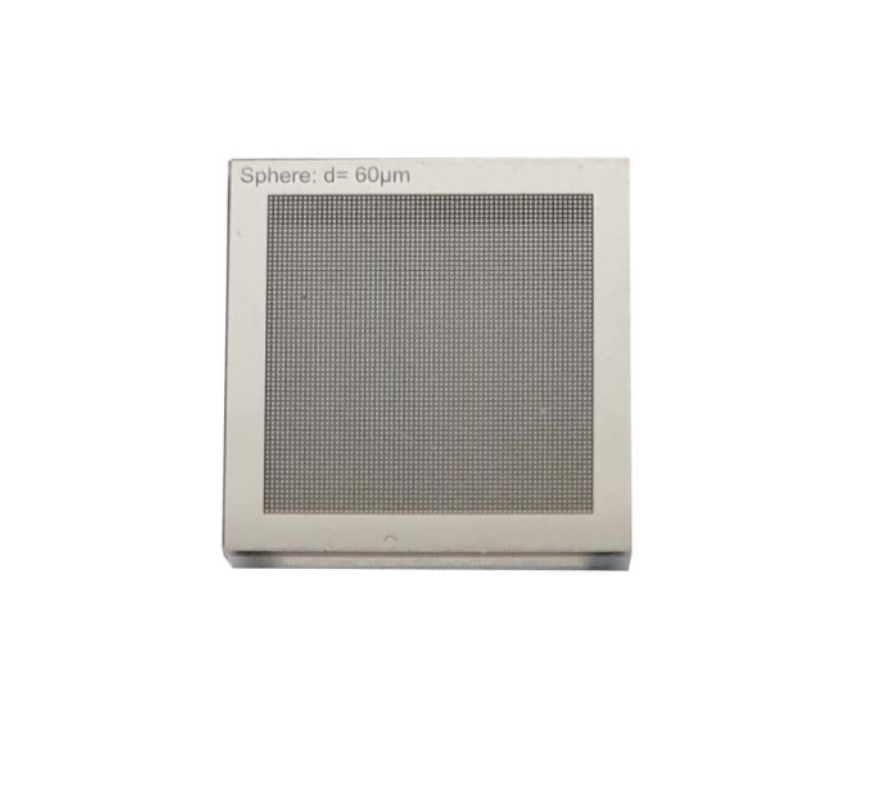

Calibration standards

Regular calibration is essential to ensure long-term measurement accuracy. Our calibration standards are traceable and comply with international standards. They are ideal for system control, quality assurance, and validation of your measurement processes.

Vibration isolation

Even slight vibrations can negatively affect high-precision 3D measurements. Our vibration isolation systems reliably minimize mechanical disturbances—whether caused by machines, building vibrations, or environmental influences. This ensures stable and reproducible measurement results even in sensitive environments.

Why GBS?

We measure, analyze, and visualize technical surfaces in 3D – from tool steel to semiconductor wafers. Precise. Comparable. Reproducible.

In-house product development

100 % made in Germany.

Nano precision

Measurement resolution below 1 nm.

Ready for integration

Interfaces for every production line.