3D surface measurement technology for medical technology and biomedicine

The highest standards apply in medical technology and biomedicine – both in development and in production. Our 3D surface measurement technology helps manufacturers meet these requirements reliably and efficiently.

From implants and surgical instruments to microstructured surfaces and bioactive coatings: our non-contact measuring systems capture topography, roughness, and structural details with the highest precision—quickly, reliably, and without affecting the component.

GBS metrology GmbH: Precise surface measurement technology since 1997

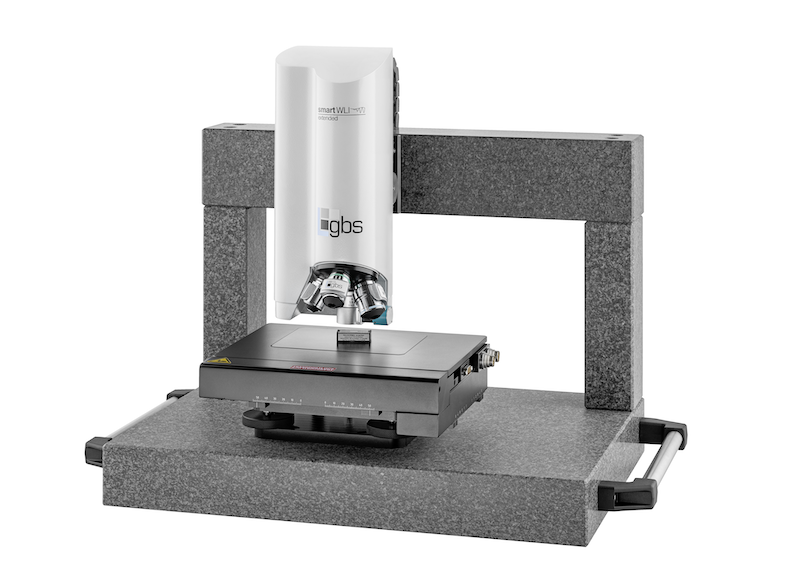

GBS metrology GmbH has been developing, manufacturing, and distributing innovative surface measurement systems since 1997. Its portfolio includes optical 3D sensors, 3D profilometers, gantry measuring devices, and production-oriented measuring stations. Thanks to powerful GPGPU technology, measurement data is processed in the shortest possible time, making the systems suitable for use both in the laboratory and inline in production.

Coherence scanning interferometry (white light interferometry) is used to capture microgeometries and surface structures with extreme precision. The “smartWLI” product line stands for high-resolution 3D surface measurement technology for micro and nanostructures.

Areas of application for 3D surface measurement technology in medical technology and biomedicine

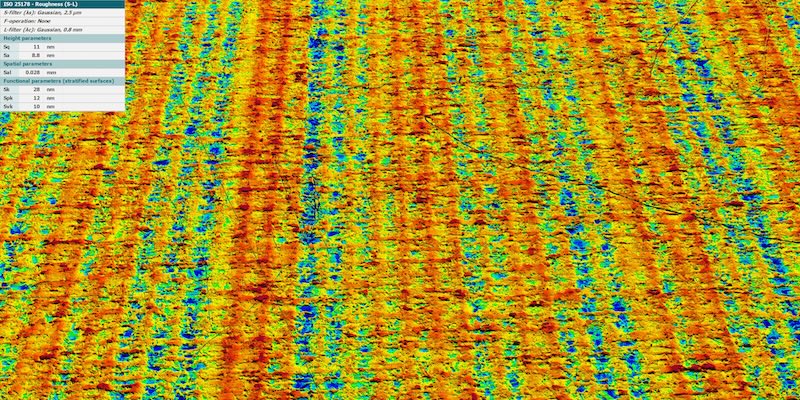

Implant surfaces

3D surface measurement technology checks the roughness and topography of implants to ensure biocompatibility and optimal healing conditions.

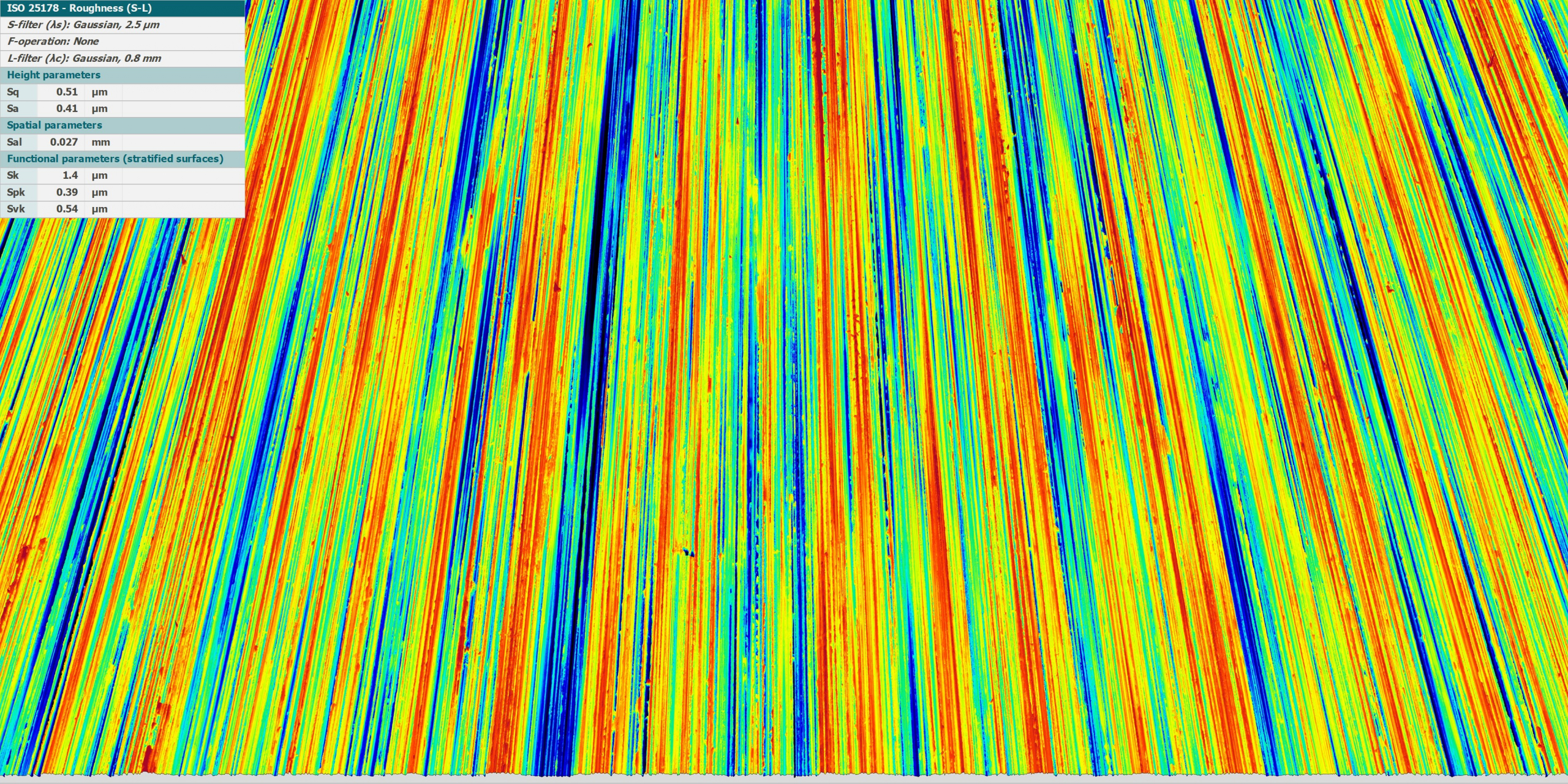

Surgical instruments

The surfaces of instruments are analyzed for roughness values and structure to ensure functionality, hygiene, and durability.

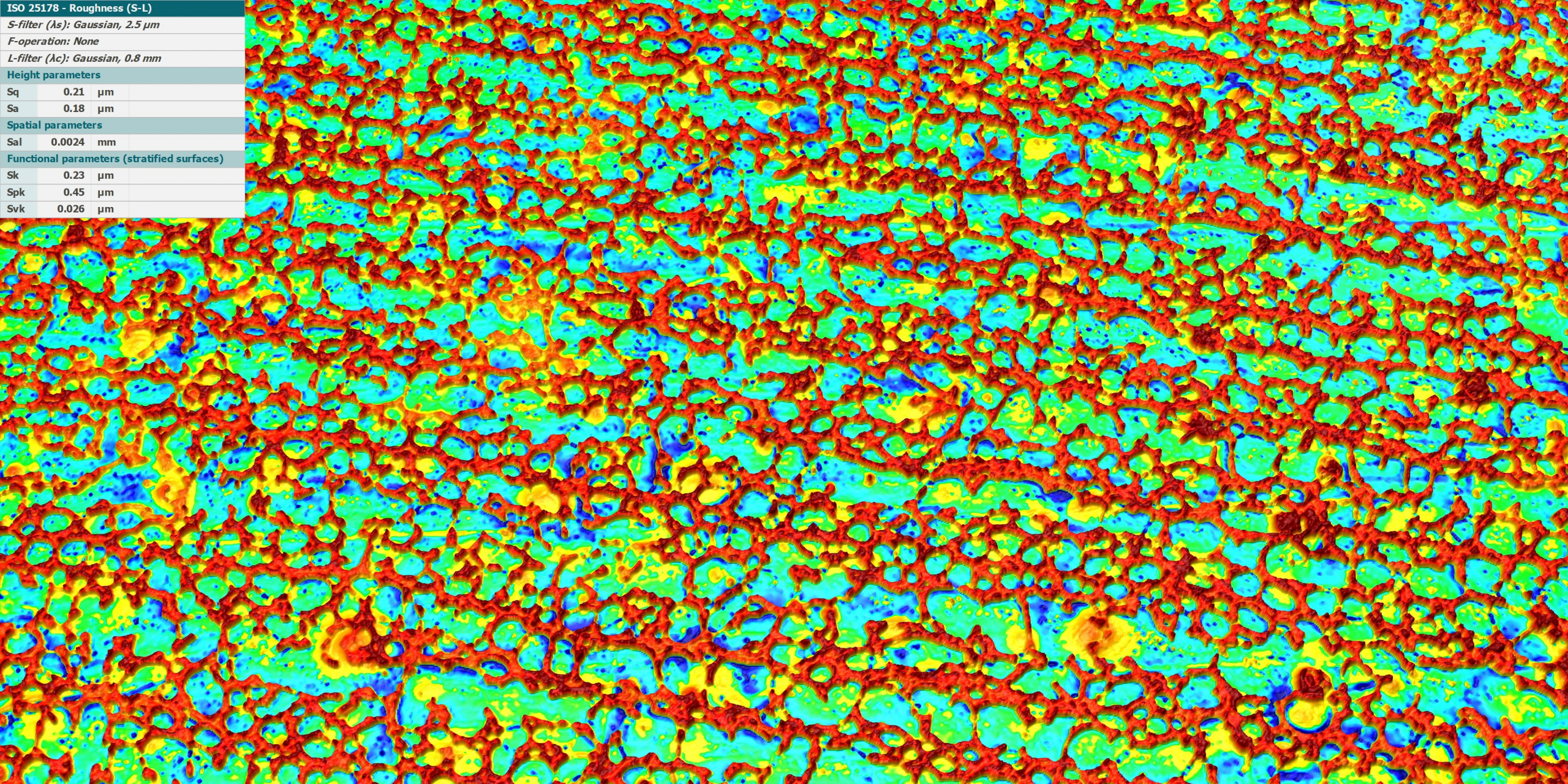

Microstructured and bioactive coatings

Measurement systems validate the uniformity and function of complex coatings that are crucial for interaction with tissue or cells.

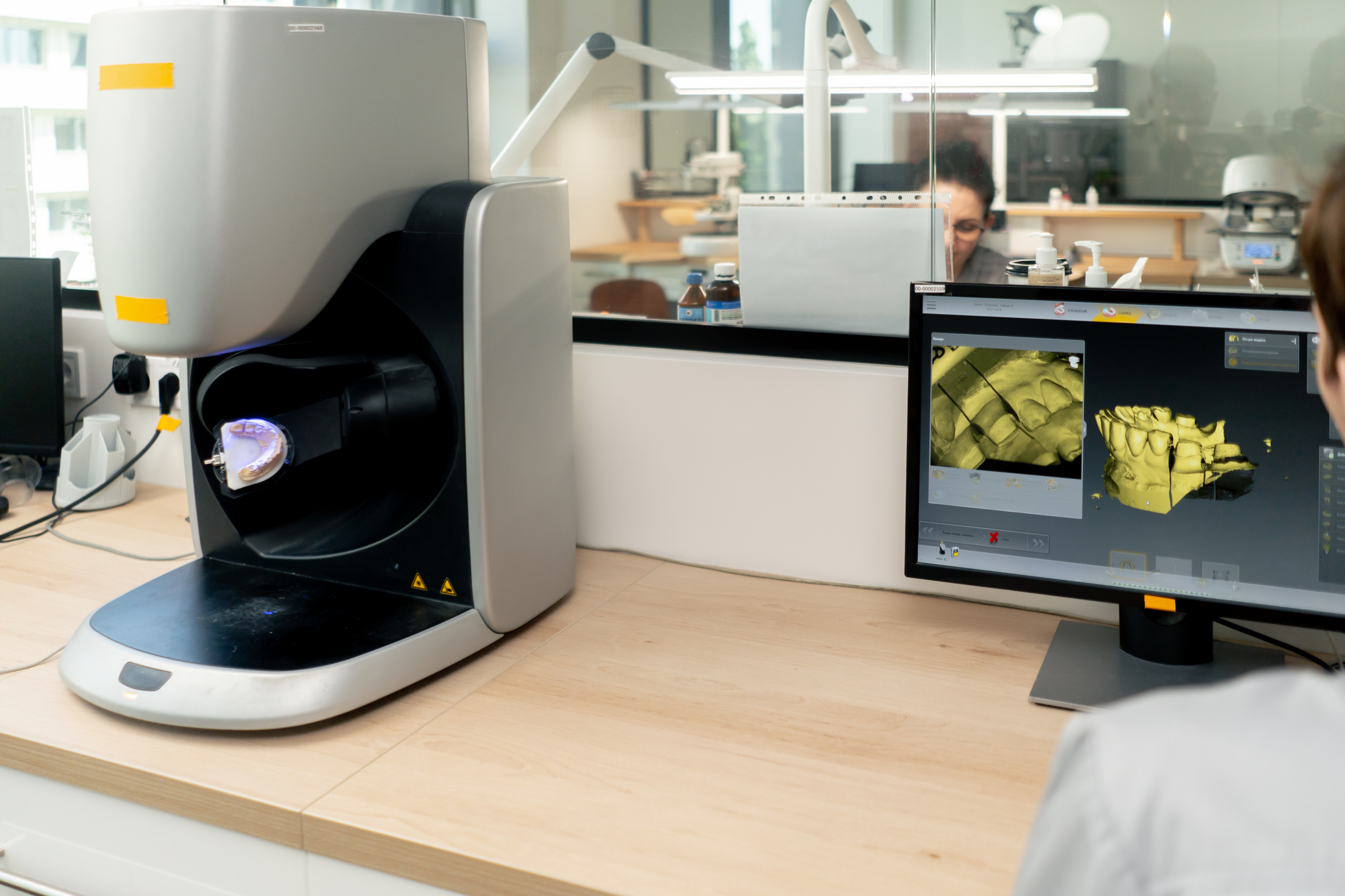

Dental technology and prosthetics

Measurement technology documents the surfaces of prostheses, crowns, and dental components and supports manufacturing and quality control.

diagnostic components

Components for analytical instruments and sensors are tested for surface defects and structure to ensure reliable measurement results.

Research and development

Precise measurement data promotes the development of new materials, surface structures, and manufacturing processes in medical technology and biomedicine.

Process and inline control

In the series production of medical products, 3D surface measurement technology enables seamless monitoring and traceability of all production steps.

Precise surface measurement technology for medical technology and biomedicine

In medical technology and biomedicine, seamless process control and verification are mandatory. GBS’s non-contact optical 3D surface measurement technology enables the exact specification and control of implants, instruments, and components.

Controlled surface roughness, topography, and microstructure are crucial for the function and service life of medical products. The measurement data supports approval and documentation in regulated markets in accordance with MDR and FDA. GBS offers modular sensors, profilometers, and software that can be flexibly integrated into production lines and laboratories.

The systems ensure fast, reliable, and audit-proof recording of all surface data for process control, quality assurance, and approval documentation. Interfaces to MES and QM systems ensure consistent data management.

Advantages of 3D surface measurement technology for medical technology and biomedicine

- Non-contact, non-destructive measurement of sensitive surfaces

- High resolution for capturing the finest structures and roughnesses

- Fast, reproducible results for research, development, and production

- Flexible integration into laboratory and manufacturing environments

- Complete traceability and audit-proof documentation

- Support for compliance with legal requirements (e.g., MDR, FDA)

- Automated data analysis and simple process control

- Suitable for a wide variety of product types, from implants to instruments

Innovative measurement technology solutions for medical technology and biomedicine from GBS

GBS offers modular sensors, profilometers, and software for medical technology and biomedicine. The systems can be flexibly integrated into production lines, laboratories, and testing facilities. Depending on the task, different sensors and lenses are used to cover different product sizes, surface types, and accuracies.

Quality assurance in medical technology and biomedicine using modern 3D measurement technology

3D surface measurement technology is a key tool in medical technology and biomedicine. It enables reliable control of surface quality, supports compliance with regulatory requirements, and increases process reliability.

Manufacturers benefit from precise, traceable measurement results, which are indispensable for both product approval and continuous quality monitoring. This creates the basis for safe, high-performance, and innovative medical devices.

What our customers say

Measuring stations for rapid testing of precision turned parts in the production environment

At the start of each shift, the dimensional accuracy of the turning tools is checked in the precision turned parts production department at Klumpp Präzisionswerk GmbH & Co. KG. To this end, workpieces from ongoing production are sent to the measuring laboratory to obtain approval for further production. In series production with multiple automatic lathes, however, the large number of measurements often leads to the laboratory becoming overloaded.

GBS metrology GmbH developed an automated measuring station. The measuring station can be installed directly in the production environment, close to the lathes. This allows workers to check their finished products themselves without any prior knowledge of measurement technology or training.

After installing the measuring station from GBS metrology, it was quickly integrated into the production process and was very well received. The reduction in personnel required in the measuring laboratory and the resulting acceleration of production approval led to a clear increase in the scope and efficiency of the manufacturing processes.

FAQ

GBS systems can be used to evaluate a wide variety of surfaces, such as implants, surgical instruments, dental products, and microstructured coatings. Even very smooth or complex structured surfaces can be measured with precision.

The measuring systems provide traceable and audit-proof data required for audits and approval documents. Automatic calibrations and complete documentation ensure compliance with all regulatory requirements.

Yes, GBS’s 3D surface measurement technology is designed for easy integration into laboratory and manufacturing environments. Interfaces to MES and QM systems enable smooth data exchange and efficient process control.