3D surface measurement technology for mechanical engineering and toolmaking

In mechanical engineering and toolmaking, the quality of each individual component determines the performance of entire systems. Our 3D surface measurement technology provides precise data on geometry, topography, and surface quality—crucial factors for dimensional accuracy, wear resistance, and fit accuracy.

GBS metrology GmbH: Innovative 3D surface measurement technology since 1997

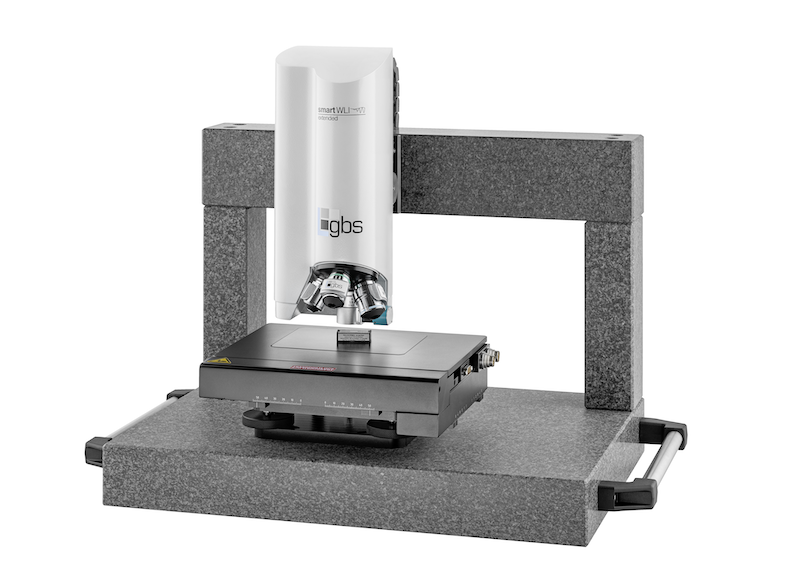

GBS metrology GmbH has been developing, manufacturing, and distributing high-precision measurement technology for recording and evaluating microgeometries, surface structures, and roughness since 1997. The product portfolio includes optical 3D sensors, 3D profilometers, gantry measuring machines, and production-oriented measuring stations.

Extremely short measurement times are made possible thanks to massive parallel image processing on powerful GPGPUs. This makes the devices suitable for both laboratory applications and for use directly in production and inline. The smartWLI product line uses white light interferometry to display a wide variety of surfaces in three dimensions with extreme resolution.

Areas of application for 3D surface measurement technology in mechanical engineering and toolmaking

Tool component testing

Components such as milling tools, cutting inserts, and dies are tested for dimensional accuracy, fit accuracy, and microdamage. The measurement technology detects geometric deviations and enables early detection of wear.

Functional area analysis

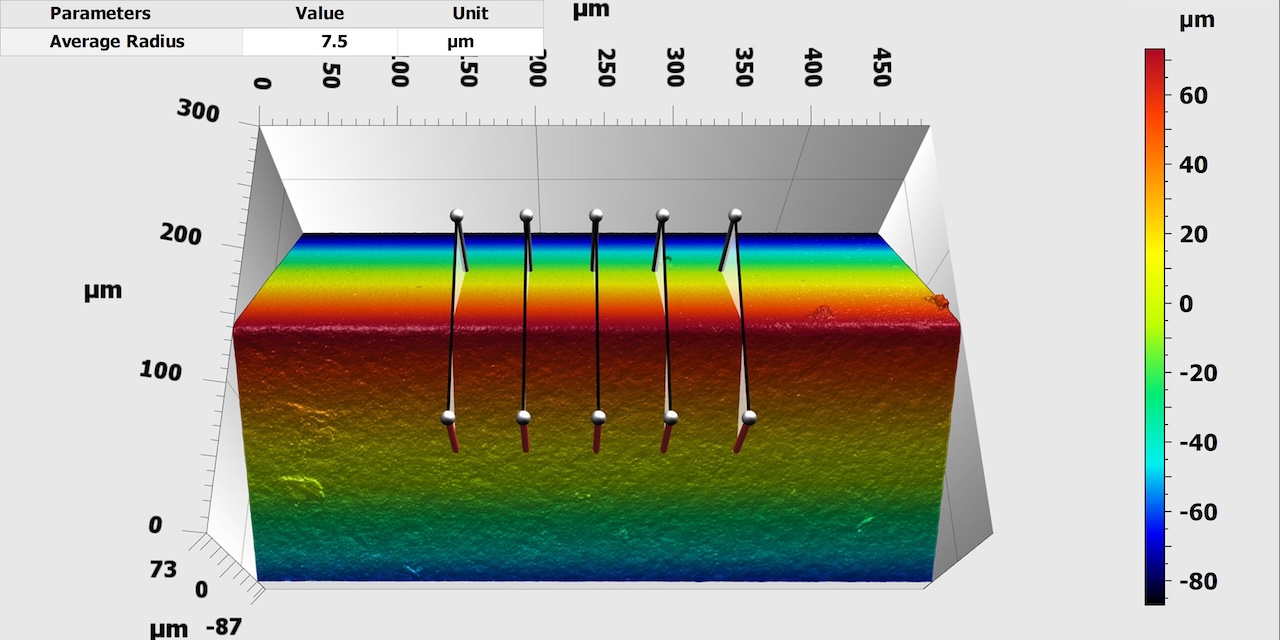

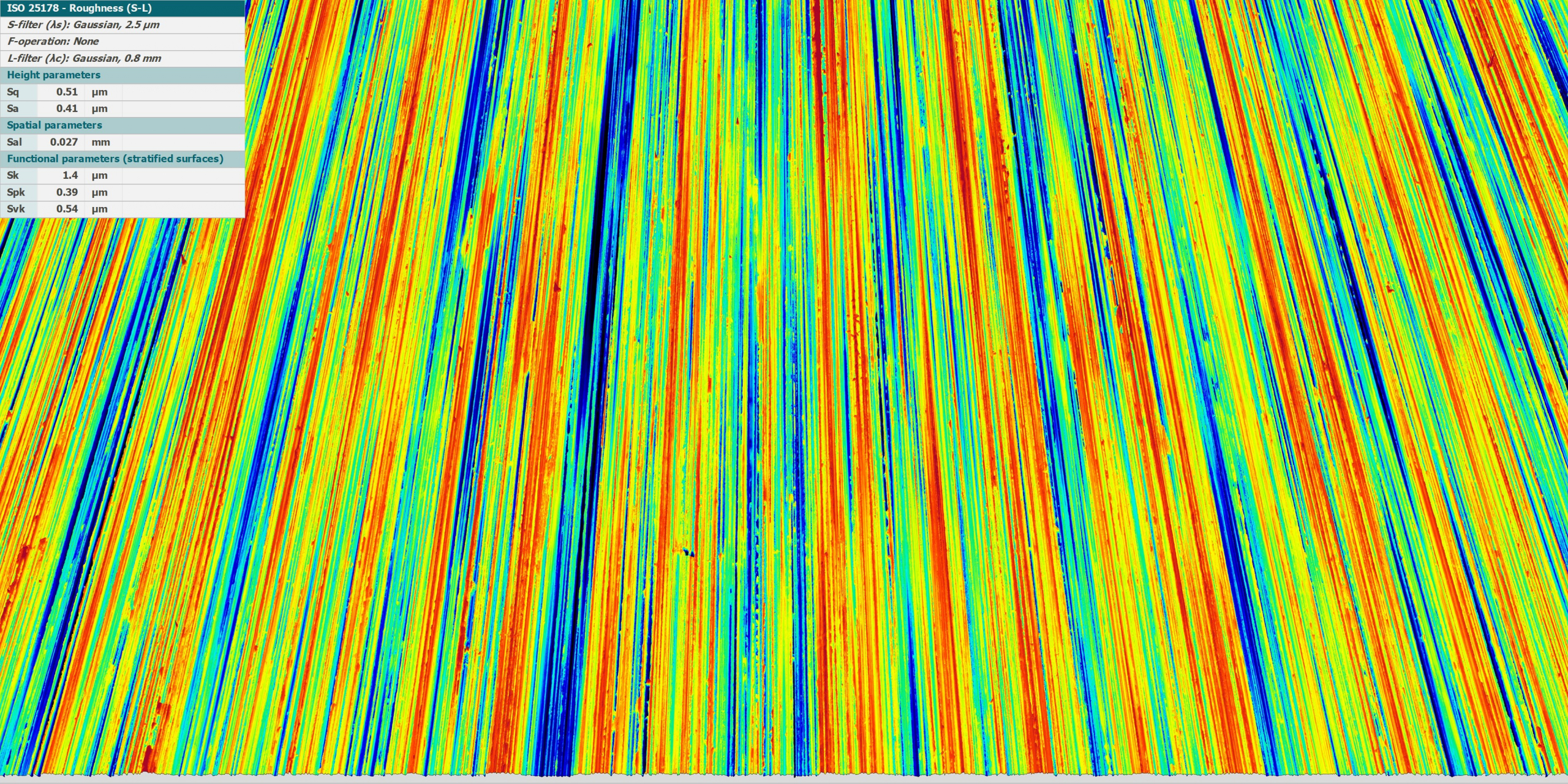

Functional surfaces, such as those on bearings, gears, or guides, are examined for roughness and topography. The evaluation of these characteristics ensures low-friction movement and optimized tribological properties.

Manufacturing process monitoring

Inline measurements during production continuously provide data on surface quality. Deviations are detected immediately, allowing processes to be adjusted and scrap reduced.

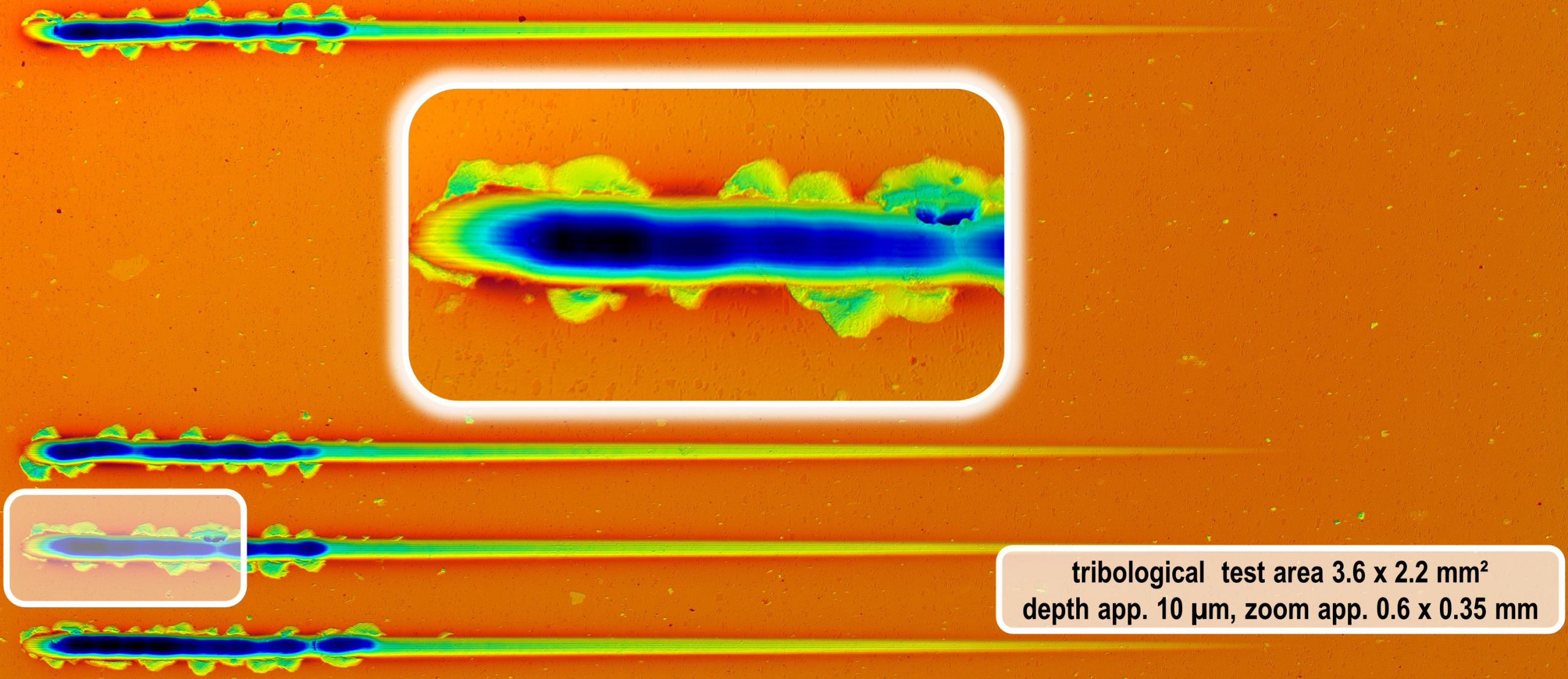

Wear analysis

The measurement technology documents material removal and wear on components such as shafts, bushings, or seals. This allows service life to be increased and maintenance intervals to be optimized.

Quality control of precision components

Complex parts with tight tolerances, including molded plates, are measured non-destructively and with repeatable accuracy. The measurement data is used for final inspection and documentation.

Development and optimization of tools

When designing new tools, 3D measurement data supports the analysis of surface structures and the optimization of manufacturing parameters for improved product quality.

3D surface measurement technology for precise quality assurance in machine and tool manufacturing

The surface finish of a workpiece influences its service life, friction behavior, and fit accuracy, which is why the analysis of functional surfaces and structural features is a fundamental part of quality assurance in mechanical engineering and toolmaking.

Precise, non-contact 3D measurement data based on white light interferometry makes it possible to comply with tolerances, check tribological properties, and detect surface defects at an early stage. Complex geometries and finely structured surfaces are captured completely and quickly, with high measurement speed and inline integration allowing real-time monitoring of production processes.

The smartWLI series from GBS metrology GmbH offers systems for manufacturing and laboratories that capture surface structures in measuring volumes up to 300 x 300 x 100 mm³ with micro- to sub-nanometer resolution and short cycle times. Integration into production lines is achieved through open interfaces and software solutions, while the MountainsMap® analysis software handles the evaluation and documentation of the measurement data.

The advantages of our 3D surface measurement technology

- Non-destructive and non-contact measurements

- High repeatability and reliability

- Fast capture of complex geometries

- Roughness measurement according to ISO 21920

- Inline integration into manufacturing processes possible

- Submicrometer resolution for detailed analyses

- Early detection of surface defects

- Support in compliance with tolerances and quality standards

Precise 3D surface measurement technology for your company

GBS metrology GmbH offers high-precision 3D surface measurement technology for machine and tool manufacturing that ensures dimensional accuracy, surface quality, and process reliability.

Thanks to innovative sensors and flexible system solutions, both individual components and complex workpieces can be tested efficiently. Integration into existing manufacturing processes enables reliable inline quality control and supports production optimization.

Advantages of 3D surface measurement technology for mechanical engineering and toolmaking

The use of 3D surface measurement technology leads to a significant reduction in scrap and rework. Short measurement times and non-destructive methods increase efficiency in production.

Repeatable measurement data ensure that every measurement under the same conditions produces identical results. This maintains product quality at a consistently high level and reliably detects any quality deviations.

The systems provide repeatable measurement data that contribute to consistently high product quality. Open interfaces and a flexible software package are available for integration. Compliance with tolerances is supported, ensuring process reliability.

What our customers say

Measuring stations for rapid testing of precision turned parts in the production environment

At the start of each shift, the dimensional accuracy of the turning tools is checked in the precision turned parts production department at Klumpp Präzisionswerk GmbH & Co. KG. To this end, workpieces from ongoing production are sent to the measuring laboratory to obtain approval for further production. In series production with multiple automatic lathes, however, the large number of measurements often leads to the laboratory becoming overloaded.

GBS metrology GmbH developed an automated measuring station. The measuring station can be installed directly in the production environment, close to the lathes. This allows workers to check their finished products themselves without any prior knowledge of measurement technology or training.

After installing the measuring station from GBS metrology, it was quickly integrated into the production process and was very well received. The reduction in personnel required in the measuring laboratory and the resulting acceleration of production approval led to a clear increase in the scope and efficiency of the manufacturing processes.

FAQ

A wide range of surface structures can be measured—from rough to highly polished surfaces. Even complex geometries and finely structured micro- and nanostructures are reliably captured.

The systems from GBS metrology GmbH feature open interfaces and a flexible software package. This enables straightforward inline integration into existing production processes.

The smartWLI series achieves sub-nanometer resolution and detects even the smallest surface defects. Precise measurement data ensure tolerance compliance and contribute to consistently high product quality.