3D surface measurement for additive manufacturing & 3D printing

Additive manufacturing opens up completely new design freedoms – but also places new demands on quality control. Our 3D surface measurement technology is particularly suitable for the precise analysis of the roughness and flatness of 3D-printed components. It detects even the smallest differences in surface structure and enables the reliable evaluation of complex geometries. The measurement systems provide detailed information about roughness values and flatness deviations, even for filigree structures.

GBS metrology GmbH: Innovation in optical surface measurement technology

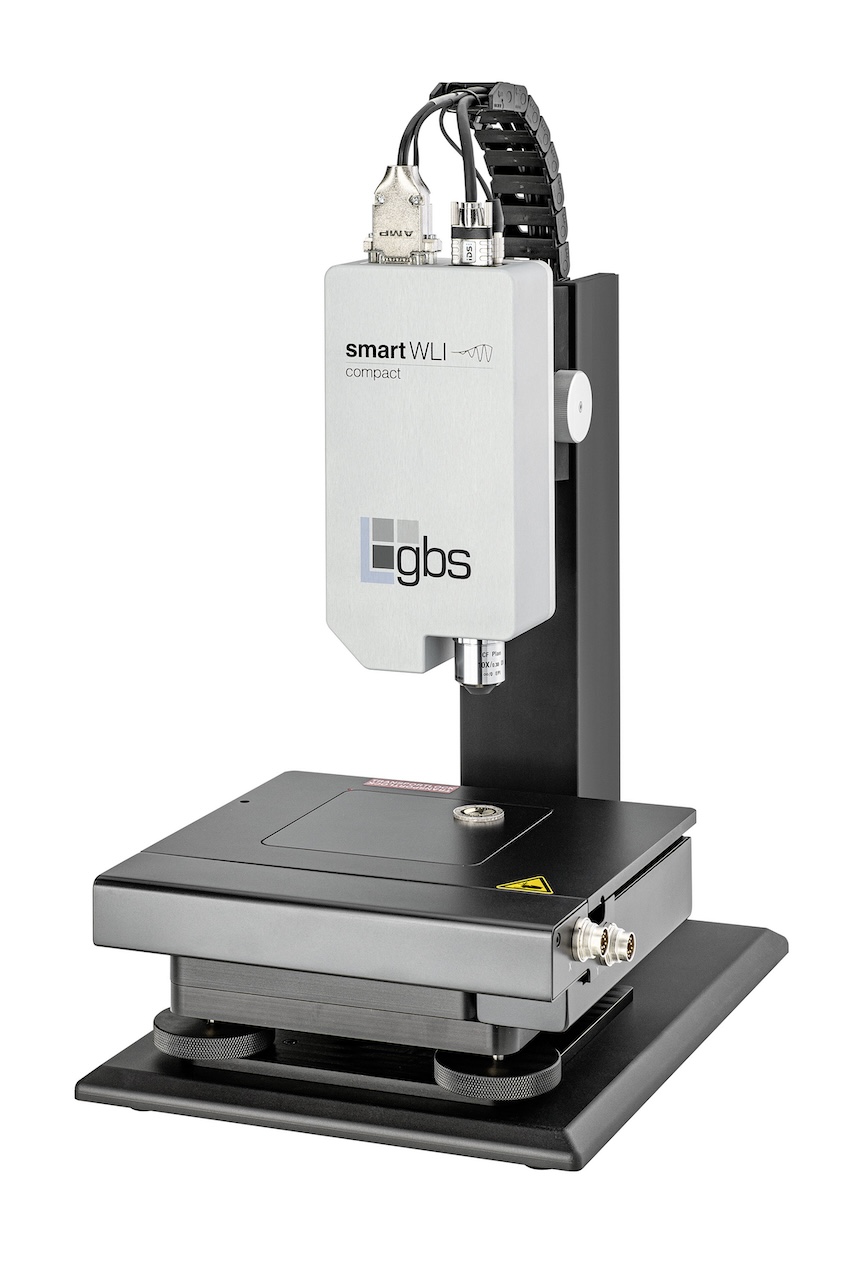

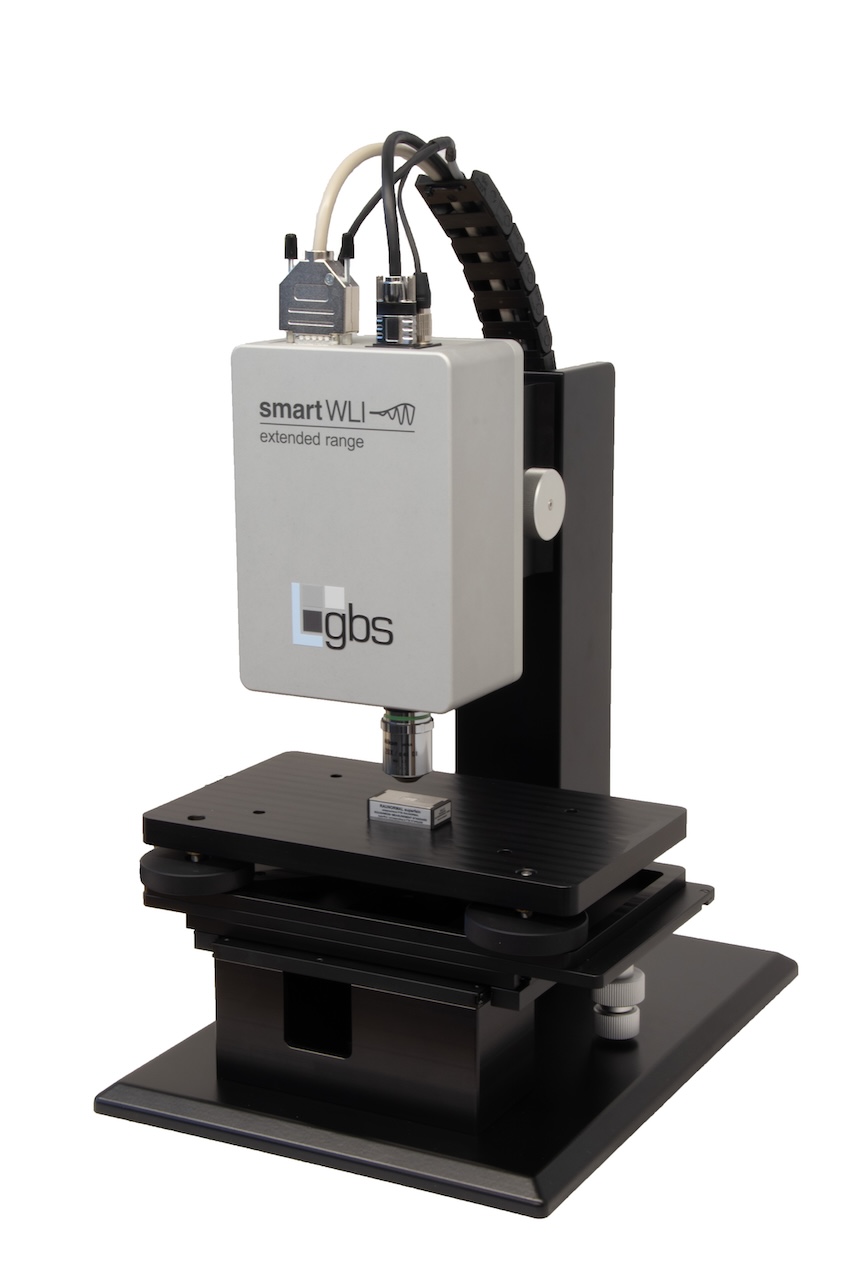

Since 1997, GBS metrology GmbH has been developing innovative solutions for the precise measurement and evaluation of microgeometries, surface structures, and roughness. Its product range includes optical 3D sensors, 3D profilometers, gantry measuring machines, and production-oriented measuring stations.

Thanks to powerful GPGPU technology, measurement data is processed particularly quickly and reliably, enabling the systems to be used both in the laboratory and directly in production. The white light interferometry used enables extremely high-resolution measurements of a wide variety of surfaces. The “smartWLI” product line stands for maximum precision in the analysis of micro and nanostructures.

Application of 3D surface measurement technology in additive manufacturing

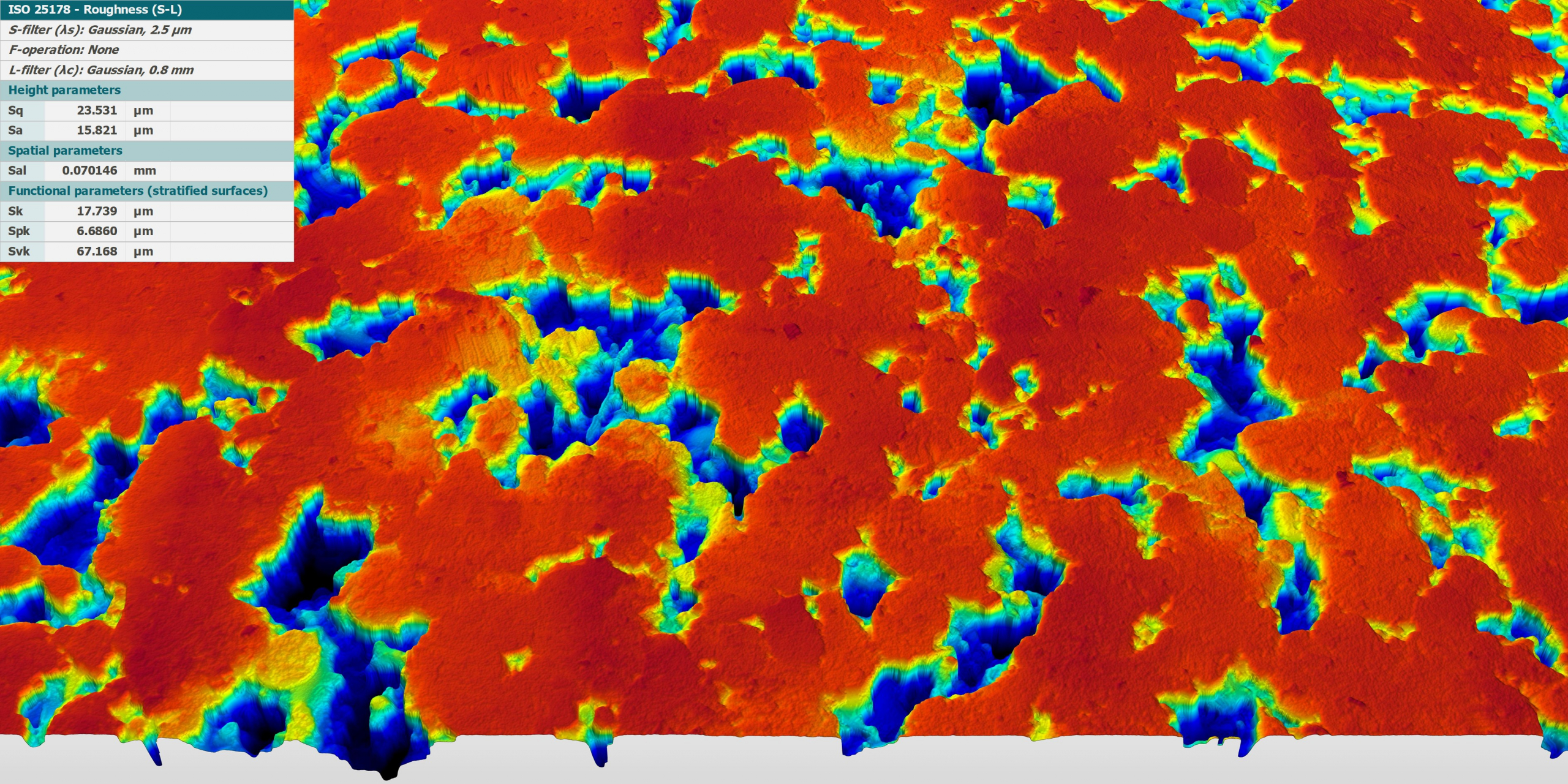

Surface analysis of additively manufactured components

3D surface measurement technology checks the roughness and structure of 3D-printed workpieces to ensure they meet functional and aesthetic requirements.

Inspection of complex geometries

The non-contact measuring method enables detailed recording of surface features, even with complex geometries.

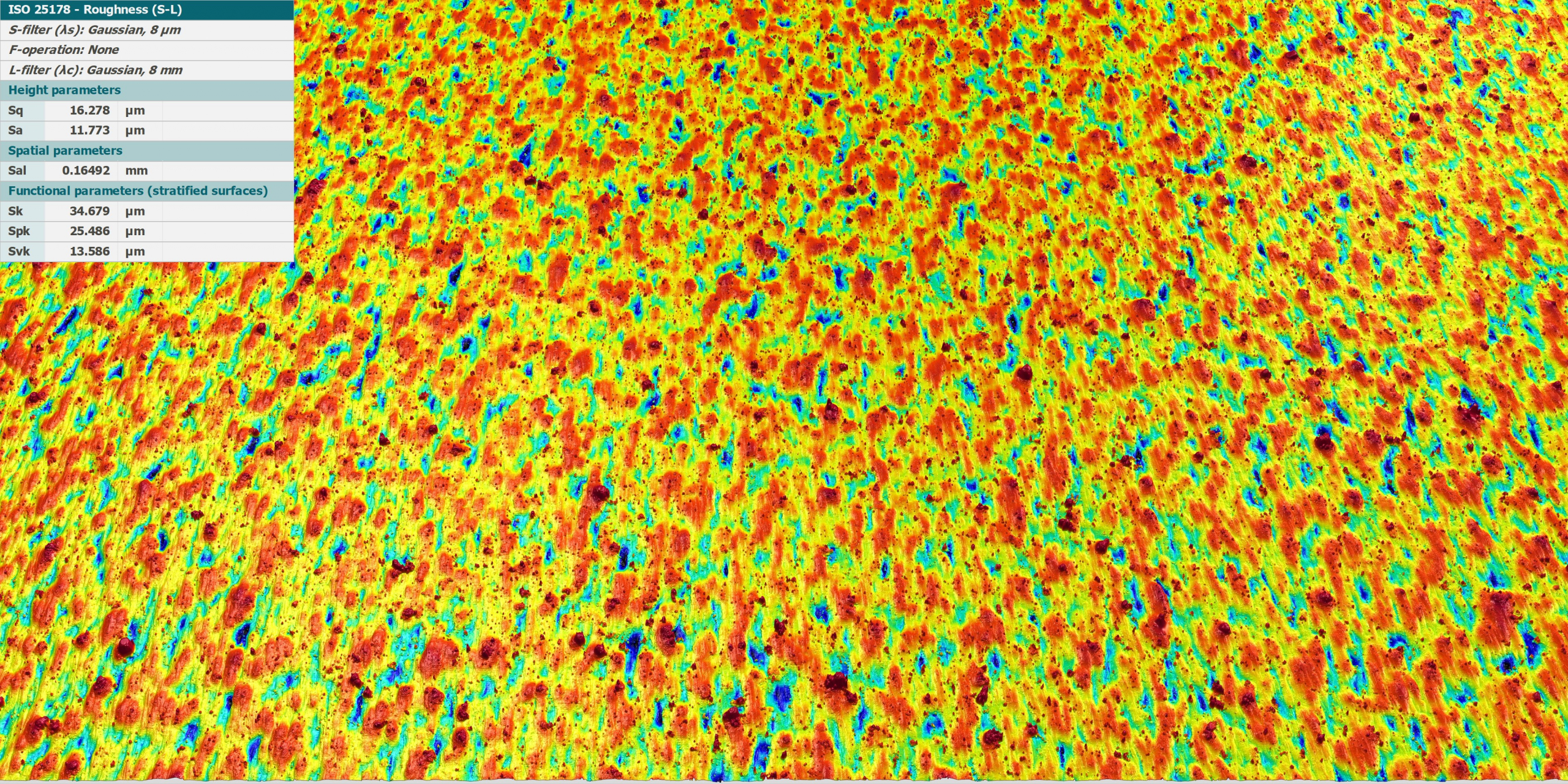

Detection of layer defects and porosity

In additive manufacturing, layer build-up, pores, or defects can be detected and evaluated immediately after printing to ensure component quality.

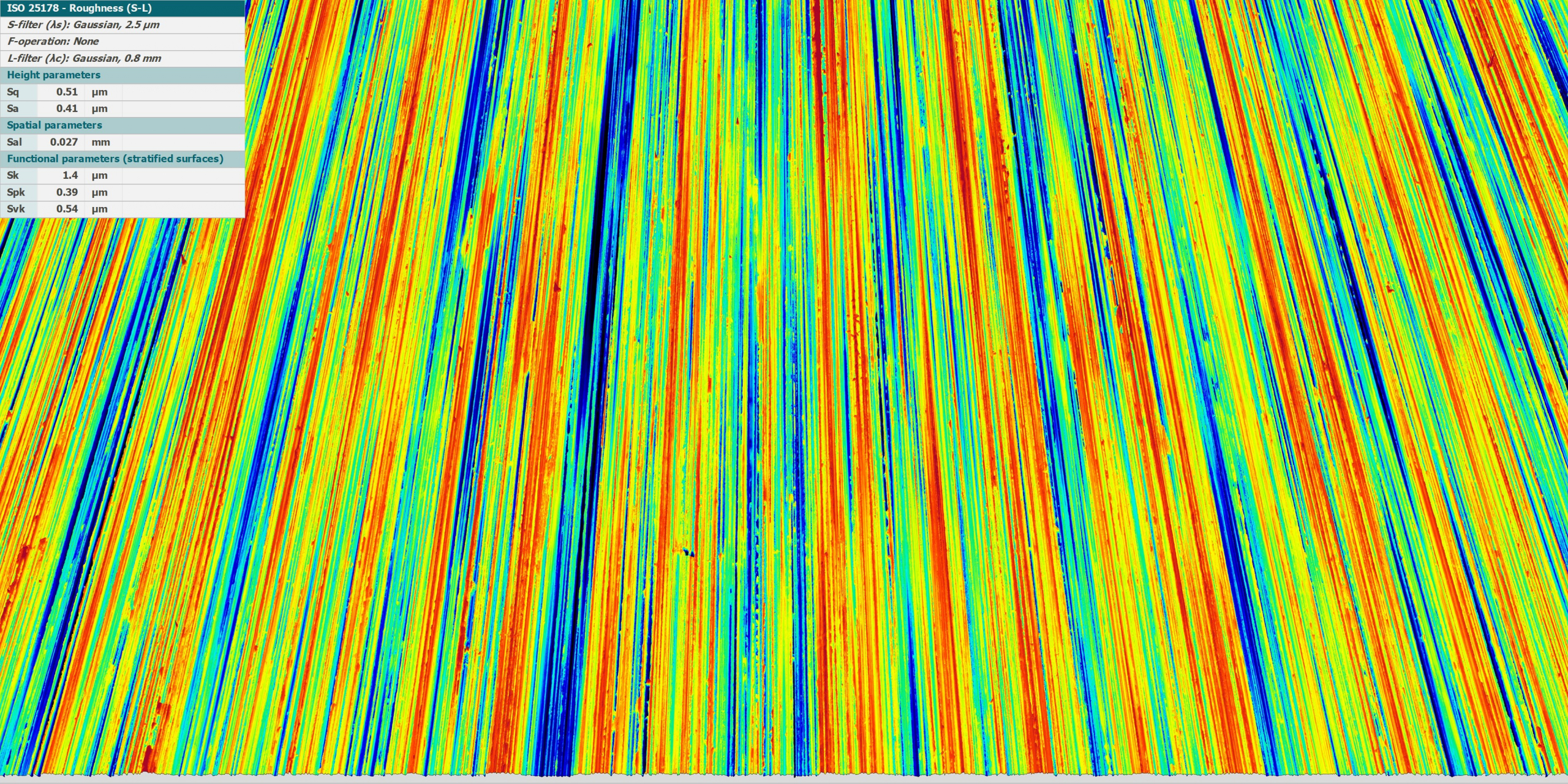

Post-processing inspection

Before and after processes such as vibratory grinding or polishing, measurement technology enables surfaces to be compared and post-processing steps to be evaluated.

Process monitoring in series production

Inline measuring systems record surface quality and deviations directly in the production process in order to reduce scrap and increase process stability.

Documentation and quality assurance

The measurement results are used for standard-compliant documentation of surface parameters and support the series approval of additively manufactured components.

Cross-material testing

Whether metal, plastic, or ceramic—the measurement technology can be adapted to various materials used in additive manufacturing and delivers comparable results.

Quality control and surface analysis in additive manufacturing

Additive manufacturing and 3D printing result in complex component structures and place special demands on quality control. The variety of materials used, such as metal, plastic, and ceramics, results in different surface characteristics, while defects such as pores, layer delamination, or dimensional deviations can occur.

GBS metrology systems offer specialized solutions for these challenges: The smartWLI series uses GPU-accelerated processing to evaluate large amounts of data in a short time, while software such as smartVIS3D and MountainsMap enable precise analysis and documentation.

This allows the roughness, shape, and dimensional accuracy of various materials to be accurately recorded, and even defects or changes after post-processing to be reliably detected.

GBS metrology’s measurement technology is flexibly configurable and delivers precise results for different materials and production requirements – from individual part inspection to series monitoring.

The advantages of our 3D surface measurement technology

- Non-contact and fast measurement of complex geometries

- High-resolution detection of roughness and shape deviations

- Reliable detection of pores, layer defects, and dimensional deviations

- Precise analysis of a wide variety of materials such as metal, plastic, and ceramics

- Flexible integration into laboratory environments and production lines

- Efficient documentation and comparison of component conditions before and after post-processing

- Support for process monitoring and series release

Precise solutions for additive manufacturing and 3D printing

GBS metrology offers optical 3D surface measurement technology that has been specially developed for the requirements of additive manufacturing and 3D printing. The systems enable fast, non-contact analysis of complex geometries and capture roughness, dimensional accuracy, and defects with high resolution. Manufacturers benefit from flexible measurement solutions for metal, plastic, and ceramics—from prototypes to series production.

3D surface measurement technology for additive manufacturing & 3D printing

Systematic monitoring of surface quality using optical 3D measurement technology ensures that components will function properly in later use. Faults are detected early on, which reduces rework and scrap.

The measurement results are available quickly and enable efficient process control. The documentation of the data supports series approval and meets the requirements of standards and customer specifications. Prototypes and series production benefit equally from the detailed analysis.

Optical 3D surface measurement technology allows measurements to be taken in real time and results to be evaluated immediately. This means that defective components can be identified immediately and removed from the production process, reducing waste and increasing efficiency.

What our customers say

Measuring stations for rapid testing of precision turned parts in the production environment

At the start of each shift, the dimensional accuracy of the turning tools is checked in the precision turned parts production department at Klumpp Präzisionswerk GmbH & Co. KG. To this end, workpieces from ongoing production are sent to the measuring laboratory to obtain approval for further production. In series production with multiple automatic lathes, however, the large number of measurements often leads to the laboratory becoming overloaded.

GBS metrology GmbH developed an automated measuring station. The measuring station can be installed directly in the production environment, close to the lathes. This allows workers to check their finished products themselves without any prior knowledge of measurement technology or training.

After installing the measuring station from GBS metrology, it was quickly integrated into the production process and was very well received. The reduction in personnel required in the measuring laboratory and the resulting acceleration of production approval led to a clear increase in the scope and efficiency of the manufacturing processes.

FAQ

GBS metrology’s systems operate in a non-contact manner and capture surfaces three-dimensionally at high resolution. This allows for the precise analysis of roughness, dimensional accuracy, and defects.

Optical 3D measurement technology is faster and enables the analysis of complex geometries that are difficult to access with tactile methods. The measurement is non-destructive and produces detailed results.

The systems can be configured for metals, plastics, and ceramics. This allows for the precise measurement and evaluation of a wide range of materials used in additive manufacturing.