Industries we work with

Our 3D surface metrology is used in numerous industries—anywhere where maximum precision is required for surface analysis. Whether in the automotive industry, medical technology, electronics manufacturing, or other high-tech sectors, we develop solutions that are precisely tailored to the specific requirements of our partners.

Below, we present selected industries in which our technologies are used on a daily basis – and show how our measurement technology contributes to quality assurance, process optimization, and innovation.

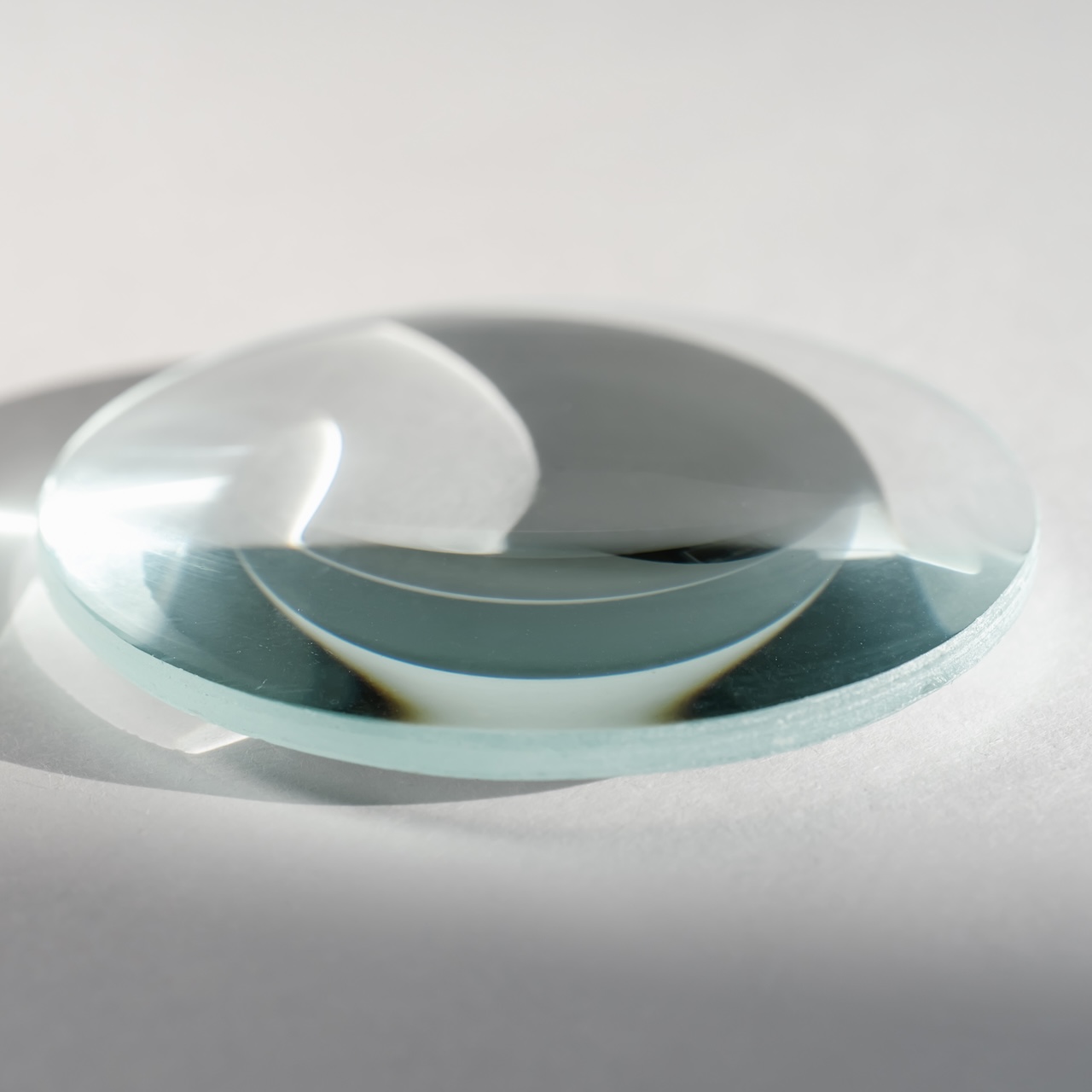

Optical Components

Automotive & Aerospace

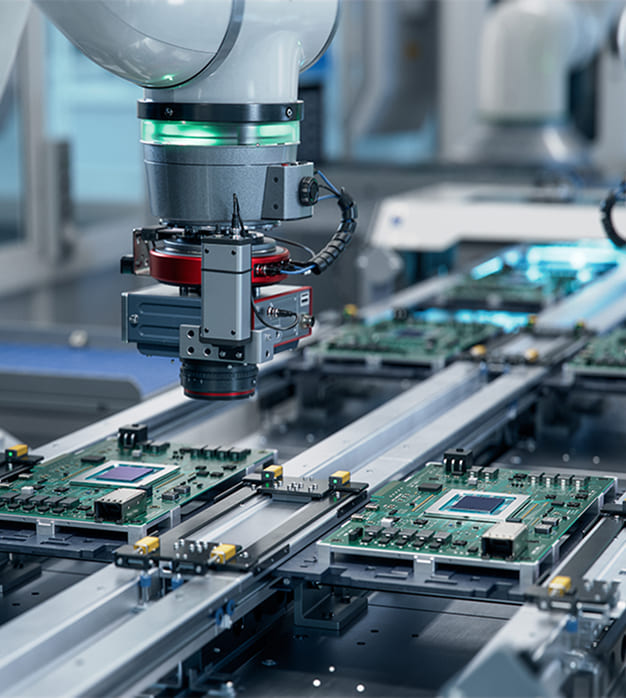

Semiconductors & Wafers

Microsystem technology

Machine & tool manufacturing

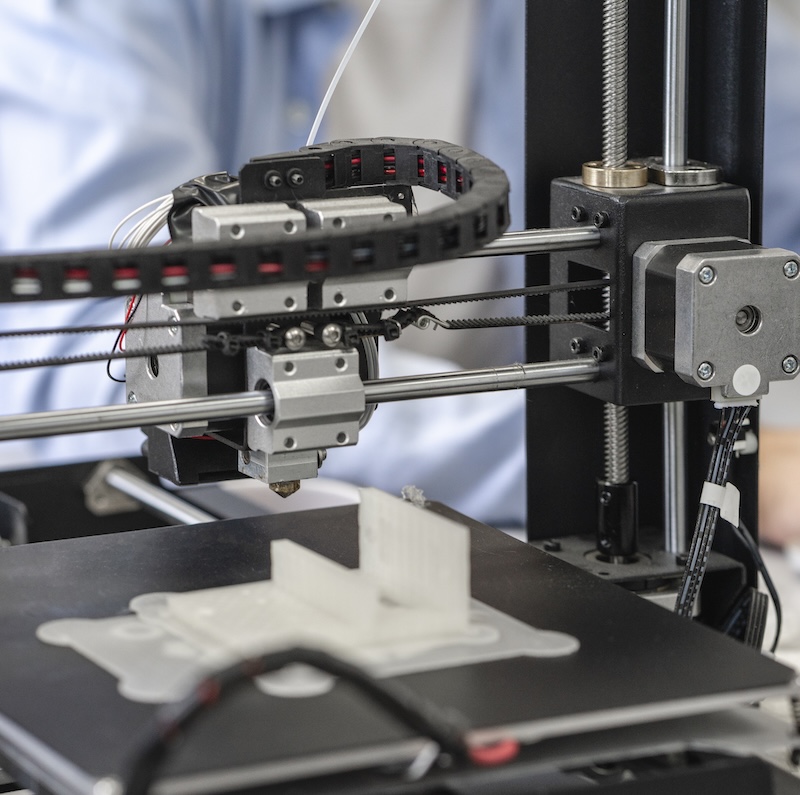

Additive manufacturing & 3D printing

Medical technology & biomedicine

Surface metrology from GBS metrology

GBS metrology GmbH has been developing, manufacturing, and distributing high-precision 3D surface measurement systems since 1997.

Our white light interferometry captures micro- and nanostructures with maximum resolution. Thanks to powerful GPGPU technology, image processing and measurement are extremely fast – ideal for laboratory, inline, and production environments. With the smartWLI product line, we offer specialized solutions for research, quality assurance, and demanding industrial applications.

Why GBS?

We measure, analyze, and visualize technical surfaces in 3D—from tool steel to semiconductor wafers. Precise. Comparable. Reproducible.

Years of market experience

industrial partners

Made in Germany

systems installed in the last 5 years

What our customers say

Measuring stations for rapid testing of precision turned parts in the production environment

At the start of each shift, the dimensional accuracy of the turning tools is checked in the precision turned parts production department at Klumpp Präzisionswerk GmbH & Co. KG. To this end, workpieces from ongoing production are sent to the measuring laboratory to obtain approval for further production. In series production with multiple automatic lathes, however, the large number of measurements often leads to the laboratory becoming overloaded.

GBS metrology GmbH developed an automated measuring station. The measuring station can be installed directly in the production environment, close to the lathes. This allows workers to check their finished products themselves without any prior knowledge of measurement technology or training.

After installing the measuring station from GBS metrology, it was quickly integrated into the production process and was very well received. The reduction in personnel required in the measuring laboratory and the resulting acceleration of production approval led to a clear increase in the scope and efficiency of the manufacturing processes.

Certified quality according to ISO 9001

Quality and process reliability are our top priorities. GBS metrology GmbH is certified according to DIN EN ISO 9001 – a clear sign of our consistent focus on quality, transparent processes, and continuous development in the interests of our customers.

Our mission:

To develop measuring systems that are not only extremely precise, but also practical, flexible, and powerful – for quality assurance that goes one step further.