Optical 3D Profiler for Roughness Measurement

Recent advances in optical roughness measurement have fundamentally transformed surface metrology – now achieving measurement rates of several million points per second.

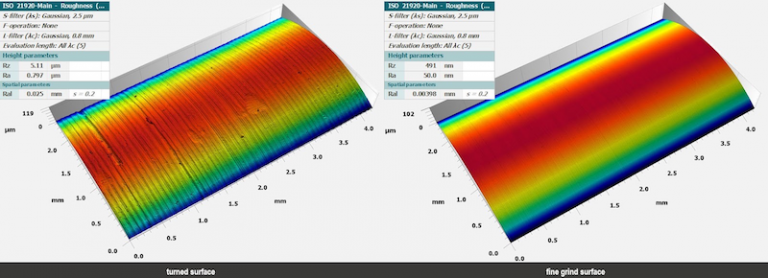

The latest optical profilers capture complex surfaces rapidly, with high resolution, and in full compliance with ISO 21920.

In an Sc3 scenario, a measurement area of 4 × 4 mm² with a point density of 0.5 µm corresponds to an impressive 64 million measurement points, captured in under 30 seconds.

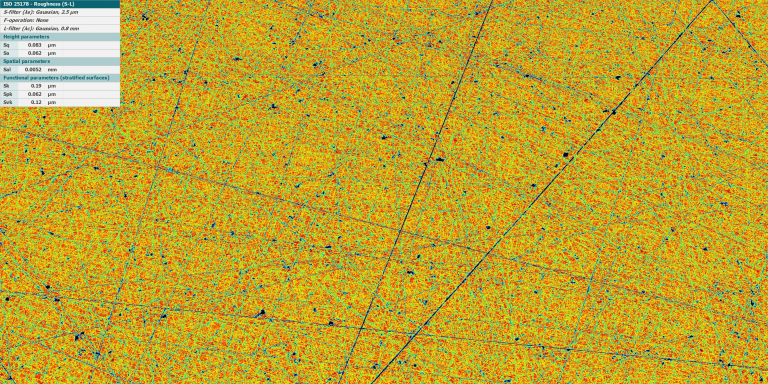

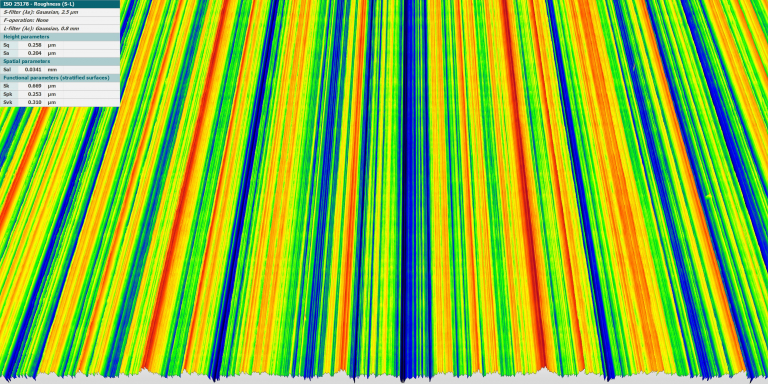

These highly sophisticated systems allow the use of specified filters (λs and λc) without compromise – comparable to traditional tactile roughness measurement methods.

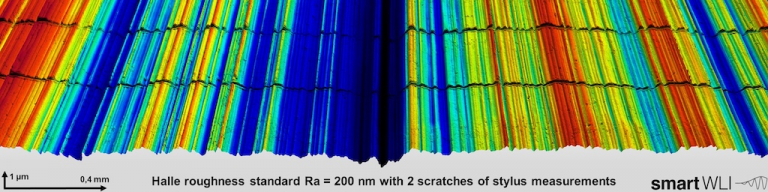

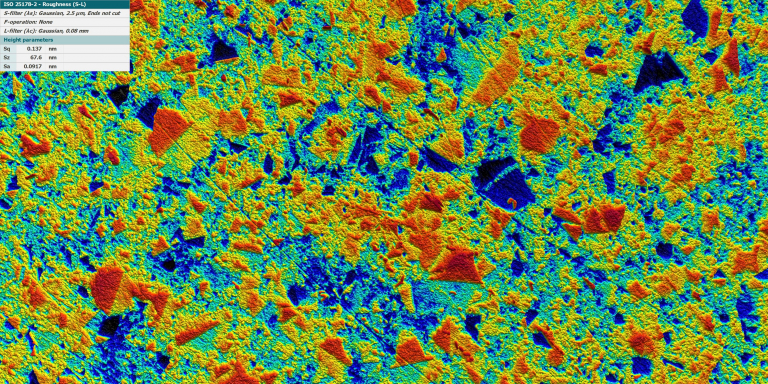

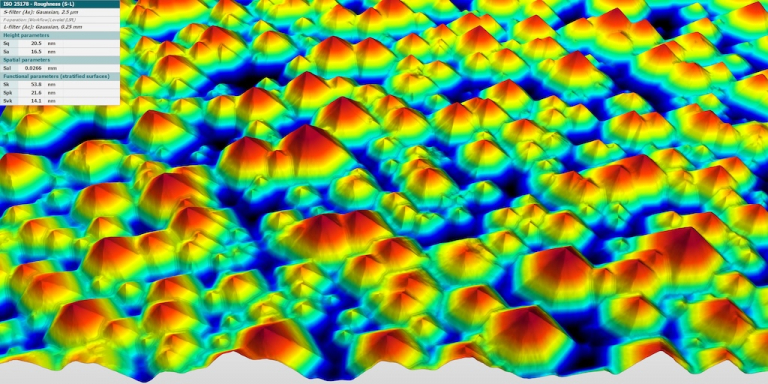

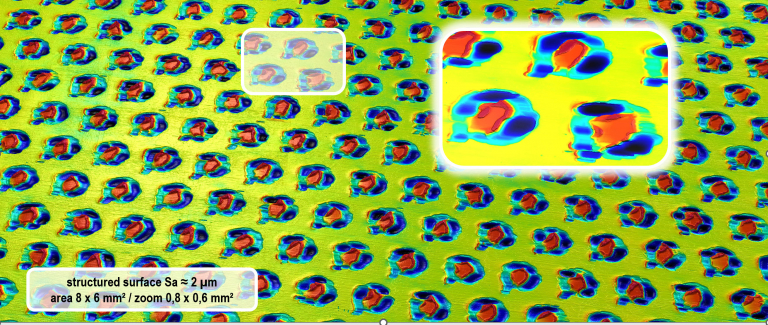

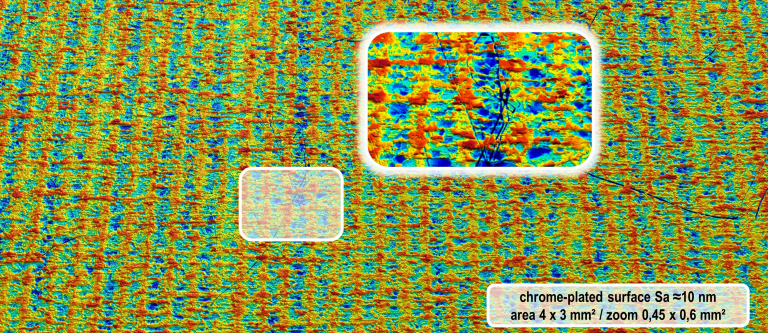

At the same time, they enable extensive three-dimensional analysis capabilities that allow structures, deviations, and defects to be precisely identified.

The ability to measure even the smallest features with significantly higher resolution greatly enhances the quality and reliability of analysis results.

With the extended capabilities of modern high-speed profilers, the typical limitations of earlier systems are eliminated.

Say goodbye to restricted measurement ranges and insufficient resolution – and experience a new era of precise, efficient, and non-contact surface profiling and roughness measurement.

Why use roughness evaluation?

Within the TracOptic project, it was found that surface effects account for around 10% of all component failures – with significant economic impact.

Modern optical profilometers make a decisive contribution by precisely identifying the causes of such failures, reducing time and cost in production.

Most machined surfaces fall within setting class Sc3 and require, for ISO-compliant roughness evaluation, a 4 mm profile length and a spatial sampling of 0.5 µm.

The latest generation of smartWLI profilometers offers a significant performance boost for roughness measurement:

With several million measurement points per second, areas of 4 × 4 mm² can now be captured at a 0.5 µm sampling rate(equivalent to 64 million points) within just a few seconds.

This high data density enables the transition from traditional 2D profile evaluation to true 3D roughness assessment – without any compromise in measurement length or resolution.

High-End Metrology from GBS

Unlock the full potential of the nimbus8 and firebolt8 – state-of-the-art 3D sensors featuring 8-MP high-speed cameras for precise roughness measurement in production, research, and quality control.

GBS metrology GmbH supports you with personalized consulting, free test measurements, and tailored solutions precisely aligned with your measurement requirements.

Benefit from our extensive experience and innovative sensor technology – from process integration to optimized practical applications.

Download

Download the full report on the advantages of the new generation of optical 3D profilometers. Explore real-world examples showcasing the new capabilities of this technology for roughness measurement.

Don’t measure just anything. Measure what matters.

FAQ

Measuring an area of 4 × 4 mm² with a spatial sampling rate of 0.5 µm requires 8000 × 8000 = 64 million measurement points.

With an effective speed of typically 2–4 million measurements per second, scanning 64 million points with the smartWLI nimbus8 / firebolt8 takes 16–32 seconds.

With a 100× objective (instead of a 10×), the profiler can measure laterally smaller structures by a factor of ten – non-contact and without limitations in vertical resolution.