GBS accelerates wafer measurements

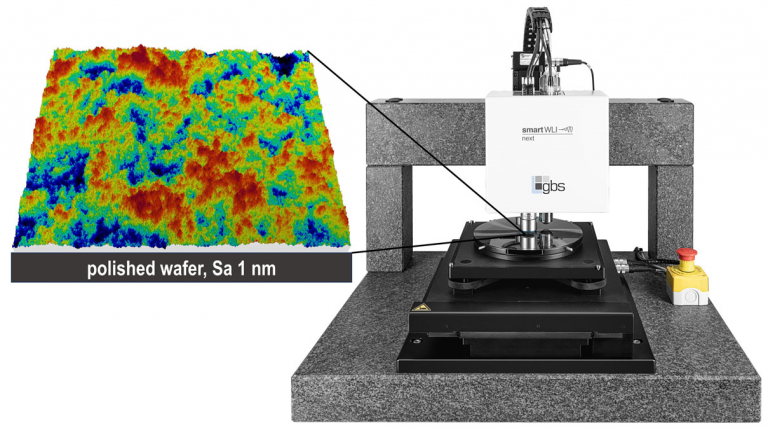

GBS, a leading company in optical 3D sensors based on coherence scanning (white-light) interferometry, now offers complete wafer measurement systems configured for use under cleanroom conditions.

10GigE cameras and real-time processing on state-of-the-art GPGPUs (General Purpose Graphic Processing Units) — delivering computing power equivalent to approximately 100 Core i9 PCs — significantly accelerate the measurement process. As a result, users can scan more wafers, more positions per wafer, and larger areas compared to alternative sensors. The Speedytec®-enabled system software allows for fully automated measurement and evaluation processes — saving both time and money.

Standard granite gantries are available for wafers up to 300 mm in diameter.

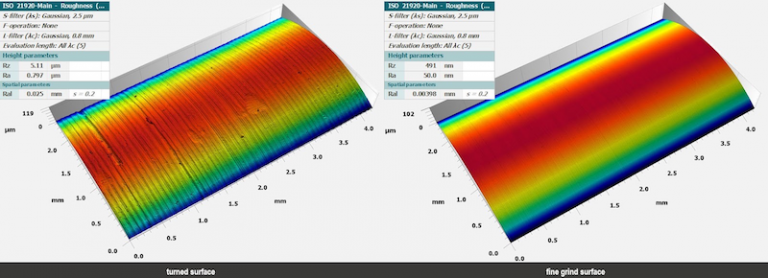

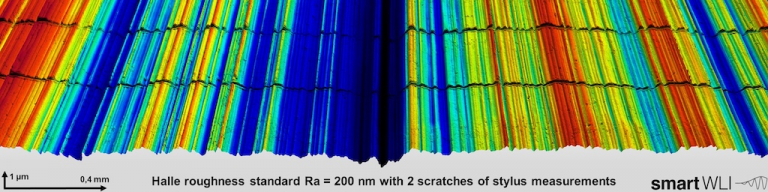

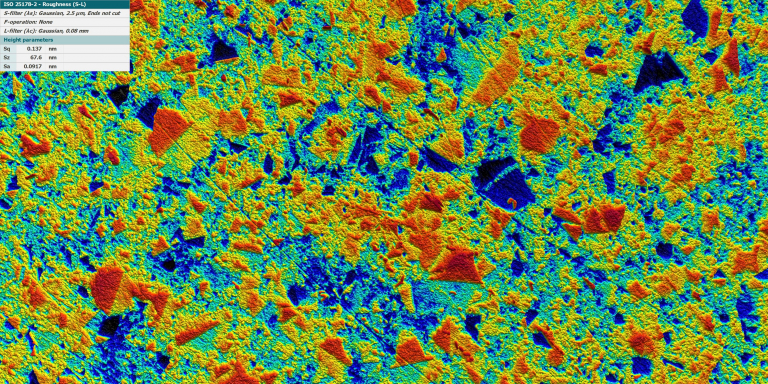

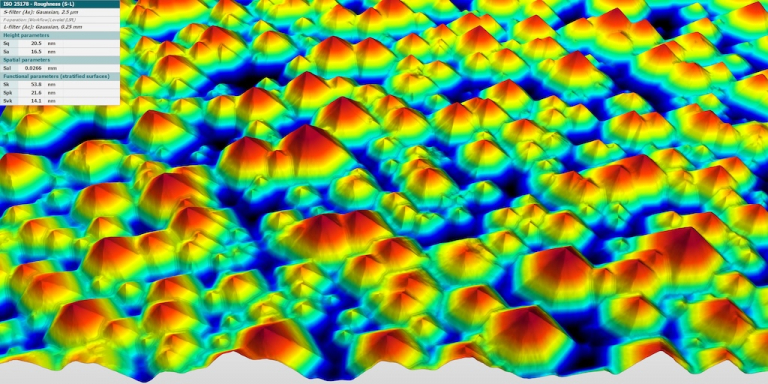

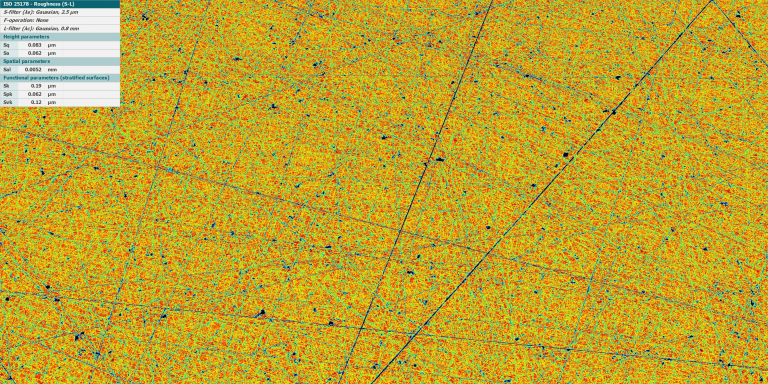

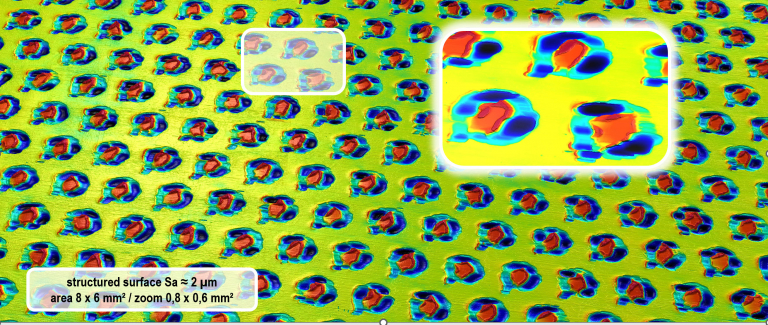

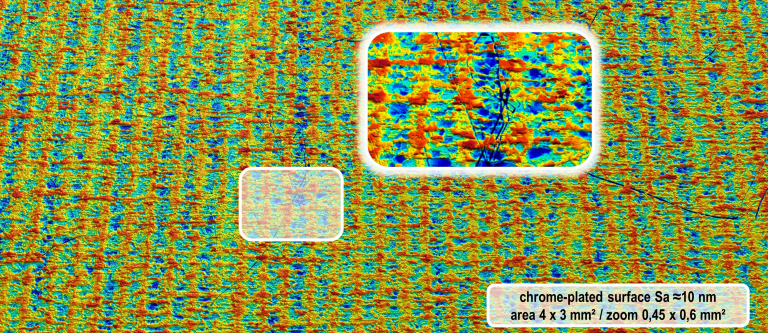

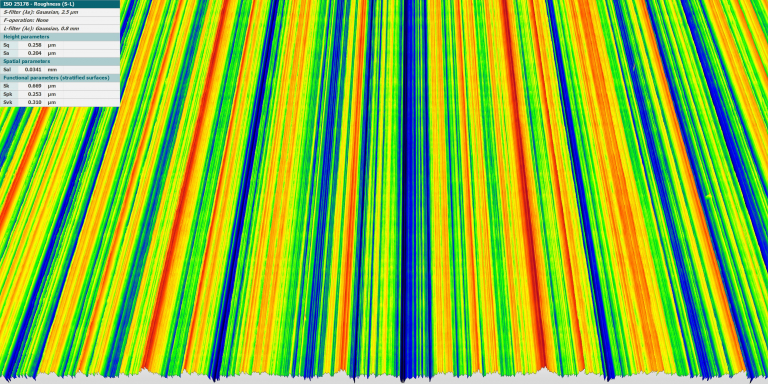

Compatible sensors such as the smartWLI dual, smartWLI next, smartWLI compact, smartWLI firebolt, and smartWLI nanoscan are equipped with high-speed cameras supporting frame rates up to 935 Hz and point resolutions up to 5 megapixels, delivering topography reproducibility down to 0.03 nm in single scans with spatial sampling as fine as 0.03 µm. The motorized Z-axis allows for height compensation up to 50 mm. The systems are optionally available with automatic tilt correction and customizable light sources for various applications.

System integrators can incorporate the sensors into their own measurement setups. The SDK provides access to all necessary sensor functions. The high-performance sensor components, combined with the Speedytec® engine, enhance overall system performance through faster measurements and a significant reduction in the effects of suboptimal environmental conditions, such as vibrations and thermal drift.