Optical 3D Sensors: Advantages of High-Resolution WLI Systems

- More details per scan / Improved lateral resolution

- Scan larger areas with a defined sampling interval

- Reduced noise in roughness measurements

- Improved acceptance angle

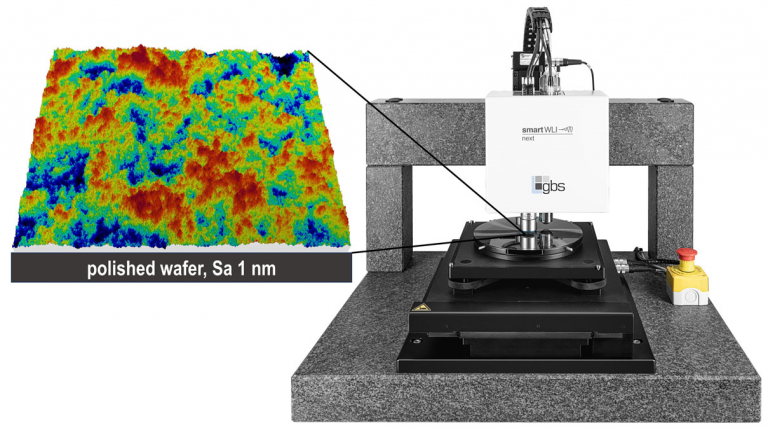

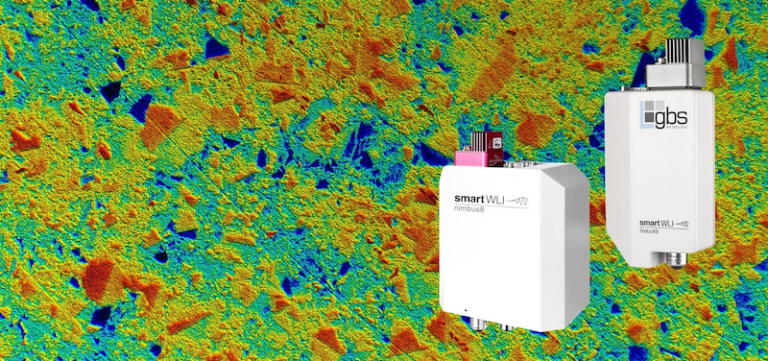

In the metrology lab, dealing with unknown samples is a common challenge for many users. When customers require precise test measurements to determine the best system configuration for their tasks, choosing the smartWLI nimbus8among various optical 3D profilometers proves to be the ideal solution. This advanced system provides accurate reference data and offers advantages such as higher speed, superior resolution, and an optimized measurement workflow.

The high-resolution WLI systems smartWLI nimbus8 and smartWLI firebolt8 offer numerous benefits, making them indispensable tools in optical profilometry and roughness measurement. These state-of-the-art sensors not only simplify the measurement process but also ensure top-quality control and precise analysis of microgeometries, microstructures, and nanostructures.

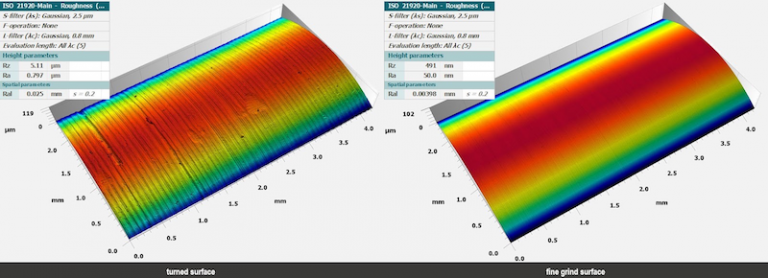

By leveraging the capabilities of these high-resolution WLI systems, professionals in metrology can gain comprehensive insights into surface topography, 3D scanning, roughness evaluation, and more. The smartWLI technology stands out for its efficiency in capturing detailed surface textures and performing thorough 3D inspections, following industry standards such as ISO21920, paving the way for the future of quality control.

Why use 8-megapixel high-speed cameras?

The basis of this advanced development is the ability to process all data in real-time on powerful graphics cards. Real-time evaluation of all images prevents SSD overflow from images captured by the high-resolution high-speed camera. Competitors often rely on binning methods, resulting in, for example, only 1.25 million measurement points with a 5-MP camera. In contrast, the smartWLI nimbus8 and smartWLI firebolt8 (without revolver) deliver significantly more information than systems with lower-resolution cameras or binning techniques.

Benefits of 8 megapixels for roughness measurement

ISO 21920 requires a spatial sampling of ≤ 0.5 µm for setting classes Sc1, Sc2, and Sc3. Equipped with an 8-MP camera, the smartWLI firebolt8 and nimbus8 allow the use of a 10× objective for roughness measurements with ISO-compliant spatial sampling of ≤ 0.5 µm.

A spatial sampling of ≤ 0.5 µm with a 10× objective means that an area of approximately 2 mm² can be scanned in a single measurement.

Summary: What can be achieved with high-resolution WLI systems?

Short measurement times

Next-generation optical 3D profilometers in the smartWLI series use 8-MP high-speed cameras combined with powerful GPU computation, achieving short measurement times despite a high number of measurement points.

Significantly more details

Based on coherence scanning interferometry (white light interferometry) combined with real-time evaluation of 3D data, the sensors provide significantly more details per scan compared to similar sensors with lower camera resolution.

Increased acceptance angle

A key aspect is the increased acceptance angle for phase-shifting analysis. In addition to the proportionally improved lateral resolution, the higher camera resolution enables the use of advanced HD-EPSI+ algorithms and reduces noise from 10 nm (VSI) to 0.1 nm for HD-EPSI+ measurements.

This allows users to measure nanostructures on inclined geometries with tilts greater than 10° at 20× magnification without leveling, saving both time and cost—especially in automated measurement processes.

Top-Quality Metrology from GBS

Unlock the full potential of the nimbus8 and firebolt8—cutting-edge high-resolution WLI systems with 8-MP high-speed cameras for precise measurements in manufacturing, research, and quality control.

GBS metrology GmbH supports you with personalized consulting, free test measurements, and tailored solutions that perfectly match your measurement requirements. Benefit from our long-standing experience and innovative sensors—from process integration to optimized practical application.

Download

Download the complete report on the advantages of high-resolution WLI systems. Discover the connections with practical examples.

Don’t measure just anything. Measure what matters.

FAQ

ISO 21920 requires a spatial sampling of ≤ 0.5 µm for Sc1–Sc3. With its 8-MP camera, the smartWLI firebolt8 and nimbus8 achieve ISO-compliant sampling of ≤ 0.5 µm for roughness measurements when using a 10× objective.

No—in fact, using 8-MP high-speed cameras and GPU-based real-time evaluation keeps measurements fast and efficient while providing higher resolution. In roughness measurement, this can even significantly reduce measurement time.

The acceptance angle increases, enabling users to measure nanostructures on inclined geometries with tilts greater than 10° at 20× magnification without leveling.