Surface Roughness Standards

| The use of surface measuring devices plays a central role in quality monitoring in metal-cutting production. On the one hand, optical 3D measuring devices from the smartWLI series offer many advantages, but on the other hand it is important to be able to correctly reproduce tactile measurement results. GBS uses various traceably certified surface standards to ensure that correct results can be achieved, systems are delivered correctly calibrated and adjusted and measurement uncertainties are reduced. |

Don’t measure just anything.

Measure what matters.

You can download a different number of files. Select one or more files to download.

This DKD-certified standard features a very smooth and precisely manufactured sinusoidal surface structure.

The certificate includes values for Ra, Rz, and Rmax with low uncertainty.

On the one hand, reproducing the roughness values requires only low resolution, which simplifies the measurement of roughness parameters using tactile instruments.

On the other hand, it places high demands on the calibration of flatness, linearity, and stitching when measuring roughness parameters with optical instruments.

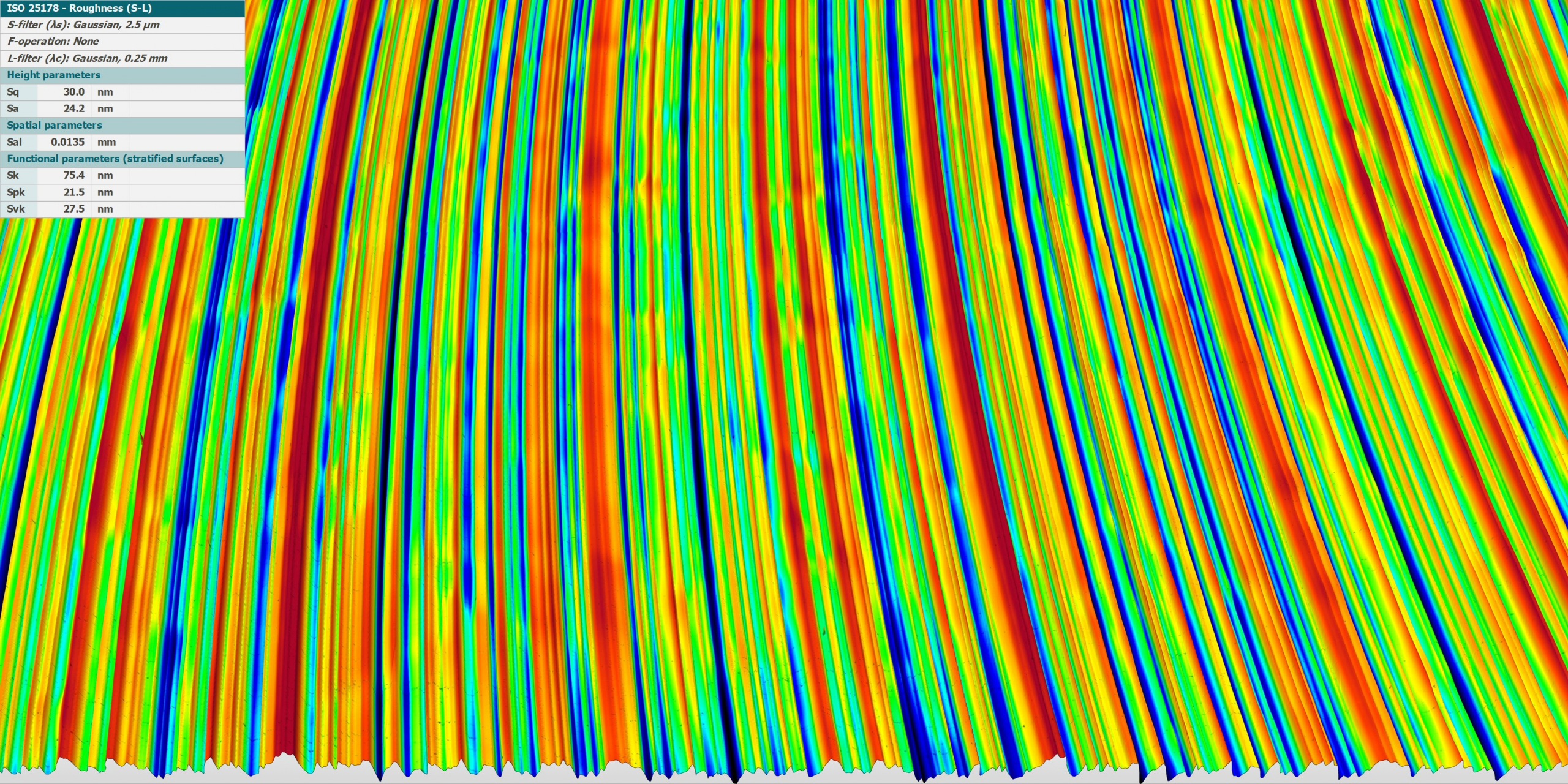

The Halle KNT 4058 features a finely structured surface that, on the one hand, closely resembles a ground surface, and on the other hand, repeats at regular intervals.

This allows for low uncertainty in the certification and measurement of surface parameters but places high demands on the resolution capability of the surface measuring instruments used.

The Halle KNT 4070 has a very smooth surface, placing very high demands on the height resolution of the measuring instrument in order to reproduce the certified roughness parameters.