Precision at the Highest Level –

Surface Metrology by GBS metrology

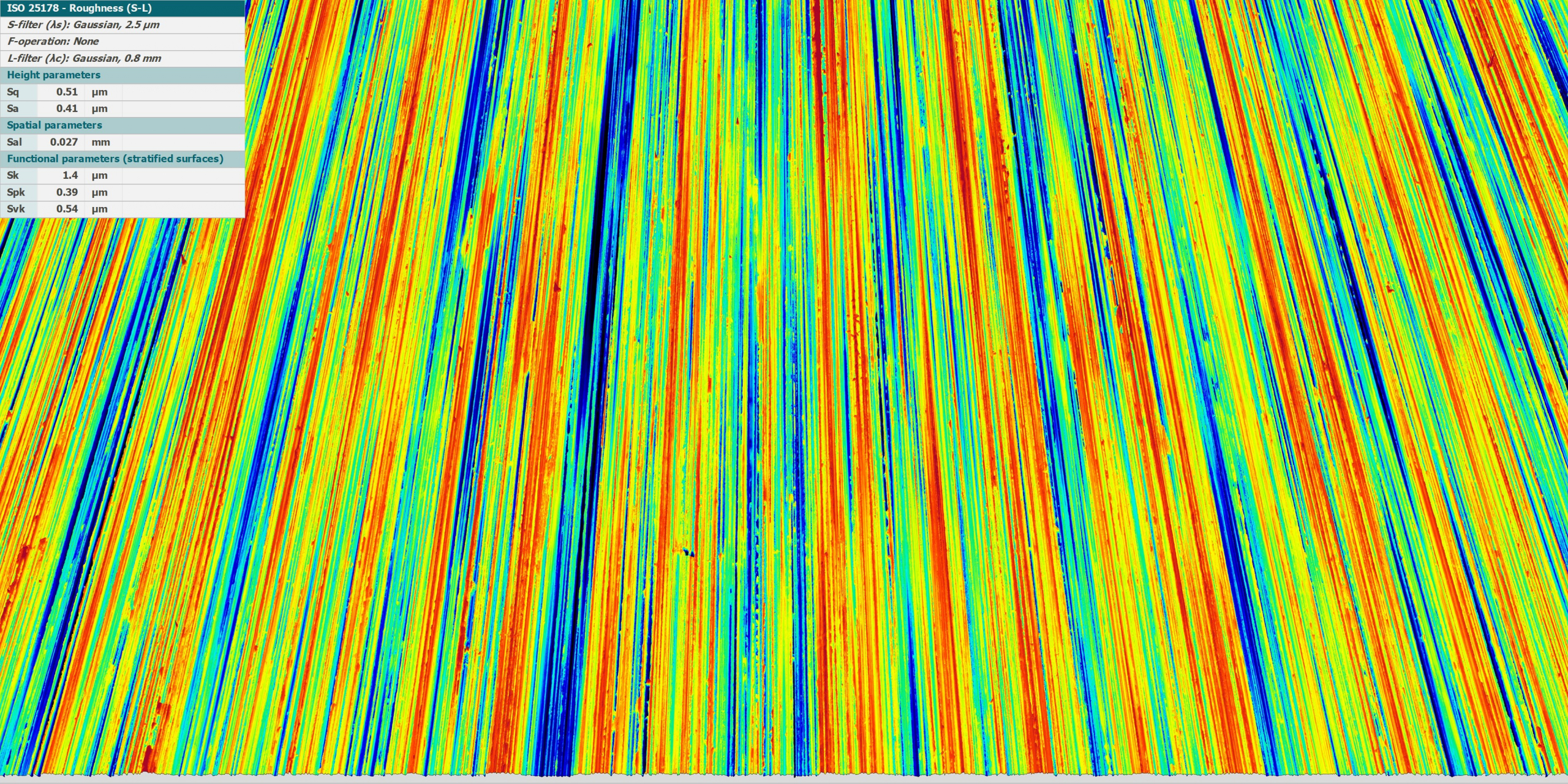

Since 1997, GBS metrology GmbH has been developing, manufacturing, and distributing high-precision systems for 3D surface metrology. Our technologies capture and analyze micro-geometries, roughness, and surface structures with maximum accuracy—from the laboratory to the production floor.

From expertise to the product

- Sensors for the application in laboratories and research

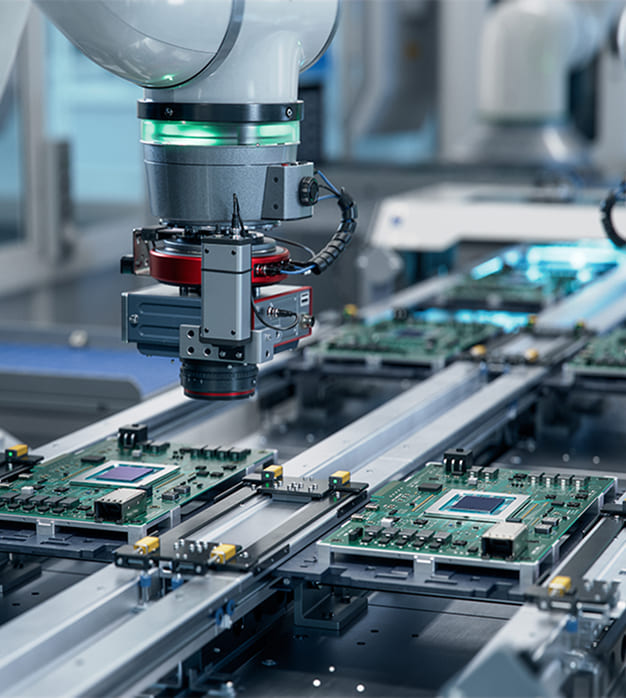

- Sensors for the application in production and integration

- Customized solutions

- Accessories (stands, objective lenses, calibration standards, vibration isolation)

- Measurement software (smartVIS3D & MountainsMap®)

The use of powerful GPGPU technology (General Purpose Graphic Processing Units) enables massively parallel image processing— resulting in extremely short measurement times. This allows our systems to be efficiently integrated not only in the lab, but also inline and close to production environments.

At the heart of our metrology systems lies white light interferometry (coherence scanning interferometry), enabling high-resolution, three-dimensional measurement of even the most complex surfaces.

With our smartWLI product line, we offer specialized solutions for the precise 3D measurement of micro- and nanostructures— developed for research, quality assurance, and demanding industrial applications.

Years of Experience

Industry Partners

Made in Germany

systems installed in the last 5 years

Our international

representatives

Through our partners and representatives in over 25 regions and countries, we have a global presence. This enables us to reliably support our customers worldwide, take local requirements into account, and offer innovative solutions directly on-site – all in line with our high standards of quality and service.

What does the

collaboration process look like?

From the initial idea to the final implementation, we guide our customers step by step. Clearly defined phases, regular coordination, and open communication ensure that projects are completed on time, with high quality, and precisely according to your requirements. Our goal: a collaborative process that builds trust and delivers sustainable results.

Initial meeting

& requirements analysis

Feasibility assessment

& solution proposal

Implementation

& training

Ongoing support

& optimization

Our advantages

GBS metrology GmbH offers advanced optical 3D metrology that perfectly combines precision, reliability, and efficiency. Our non-contact systems for roughness, microstructure, and nanostructure measurements deliver reproducible results, save testing time, and can be flexibly adapted to your individual requirements—ideal for research, development, and modern manufacturing.

In-house product development

Minimal maintenance required

Full automation possible

Faster ROI of products

First-hand support

Short measurement times – real-time evaluation on GPGPUs

Focused support for research-driven development

As part of the “Innovative Personnel” funding program, a portion of our research-oriented development work is supported by the state of Thuringia – co-financed by the European Union.

This funding enables us to strategically involve qualified specialists in innovative development projects, allowing us to further advance our expertise in optical 3D surface metrology in a targeted manner.

Our Journey

– From Vision to Precision

GBS metrology GmbH was founded in 1997 with the ambition to set new standards in optical quality assurance. What began as a small, technology-driven company has, over more than two decades, evolved into a recognized specialist in high-precision 3D metrology – serving customers from industry, research, and high-tech sectors worldwide.

From the very beginning, our focus has been on non-contact operation, precision, and practical usability of our measurement systems. Through the continuous advancement of white light interferometry and the consistent use of modern GPU-based image processing, we have been able to drastically reduce measurement times and successfully establish our systems for near-production and inline measurements.

New products. New spaces. New opportunities

An important milestone was the launch of our smartWLI product line, which has since stood for high-performance solutions in 3D measurement of micro- and nanostructures.

Our growth has also been reflected in our infrastructure: In 2022, we moved into a modern new company building, which was expanded in 2024 with an additional annex. These investments create space for innovation and further technological development – all in line with the needs of our customers and partners.

GBS metrology today

Today, our company combines many years of experience, innovative development, and the commitment to take the next technological step together with our customers – precisely, reliably, and with a future-oriented approach.

Certified quality according to ISO 9001

Quality and process reliability are our top priorities. GBS metrology GmbH is certified according to DIN EN ISO 9001 – a clear sign of our consistent commitment to quality, transparent processes, and continuous improvement for the benefit of our customers.

Our mission:

To develop measurement systems that are not only extremely precise but also practical, flexible, and high-performing – for quality assurance that takes the next step.