Requirements for the Lateral Resolution of a Profilometer

- Lateral Characterization of Surfaces

- Understanding the Autocorrelation Length Ral

- Characterizing the Lateral Resolution of Profilometers via the Lateral Period Limit DLIM

Optical profilometry has advanced rapidly in recent years. While it was once primarily evaluated by how well it could replace tactile instruments, modern optical 3D profilometers now set entirely new standards.

Thanks to innovative sensor technology, they record several million measurement points per second and deliver exceptionally high resolution in all three spatial dimensions. This performance makes them reliable reference instruments across a wide range of applications – from research and development to industrial quality control.

However, the highest possible resolution is not always the best solution. Systems with maximum magnification and top-tier cameras are technically impressive, but they can also lead to higher costs and longer measurement times. Therefore, it is crucial to know and apply the resolution actually required for the specific task. This approach significantly reduces time and costs – without compromising measurement quality.

This article explains how to determine the optimal resolution for your application and how to select the most suitable measurement system – ensuring precise, efficient, and cost-effective results.

Practical Approach to Requirements Analysis

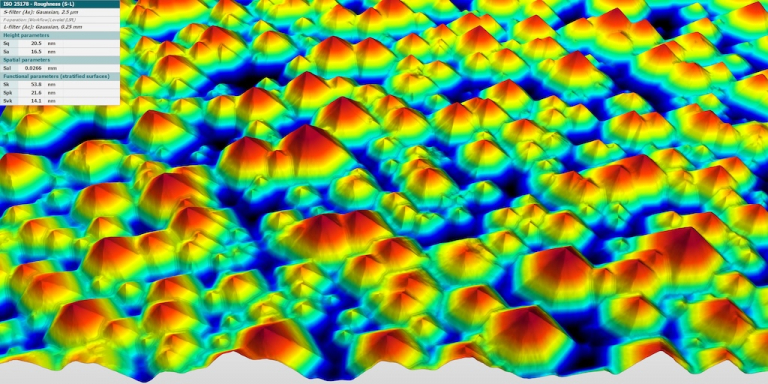

Lateral resolution plays a central role in selecting a suitable profilometer. It defines how finely the smallest surface structures can still be reliably detected and measured – and thus how precise and meaningful the measurement results will be.

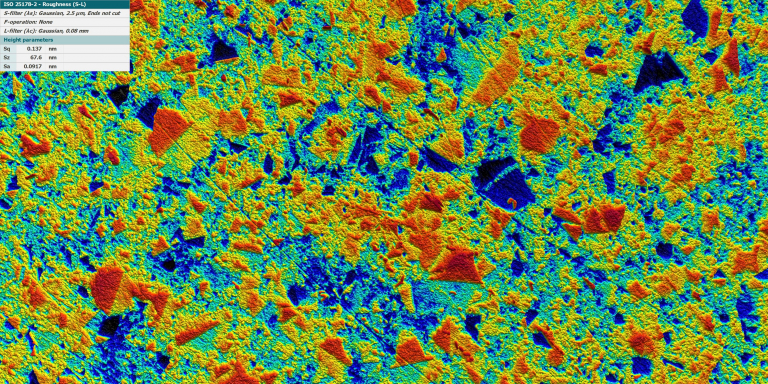

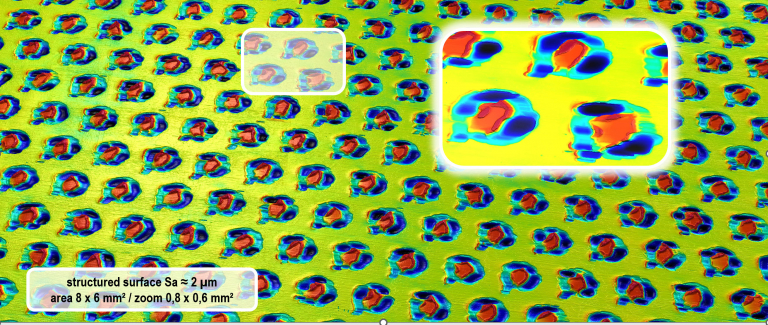

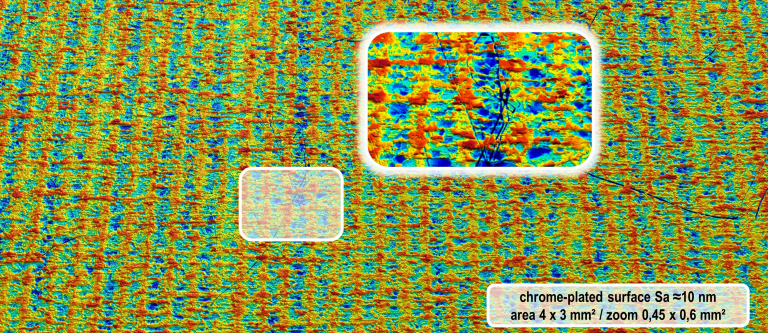

In practice, this presents a particular challenge: Surfaces subjected to roughness measurement generally do not have regular or clearly defined structures. They consist of a complex combination of random topographic features. As a result, direct comparison of different profilometers using typical marketing specifications such as resolution, measurement range, or point density is difficult – and often impossible.

To enable a reliable and comparable evaluation nonetheless, the accompanying presentation (see below) introduces a practical, application-oriented approach. At its core is the characterization of surface structures using the autocorrelation length (Ral).

This parameter describes the distance over which surface structures statistically repeat and provides a quantitative basis for determining the required lateral resolution.

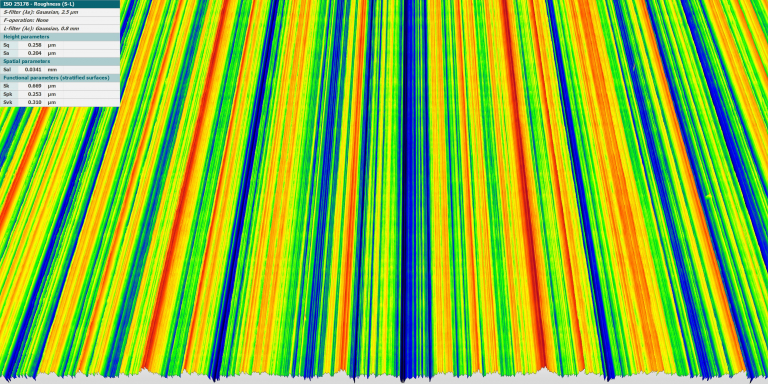

Building on this, the article demonstrates how profilometers can be classified based on their lateral period limit (DLIM)– that is, the threshold up to which periodic structures can still be reliably resolved.

This methodological approach creates transparency when assessing and selecting different measurement systems and helps users identify the instrument best suited to their specific application.

The combination of Ral analysis and DLIM classification enables a far more precise correlation between measurement task and measurement system – forming a valuable foundation for efficient, reproducible, and reliable measurement results in both research and industry.

Summary: Key Insights from the Article

ISO-compliant Evaluation

Ral and DLIM enable objective and ISO-compliant assessment of surface structures and instruments.

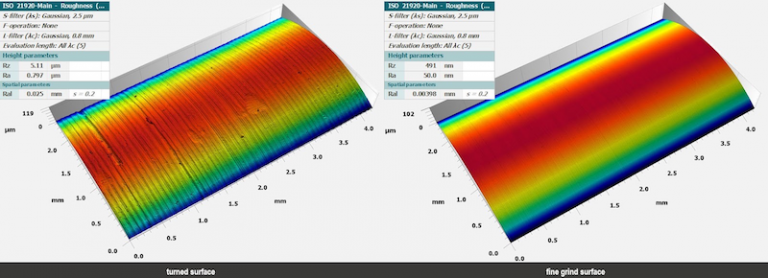

Optical vs. Tactile

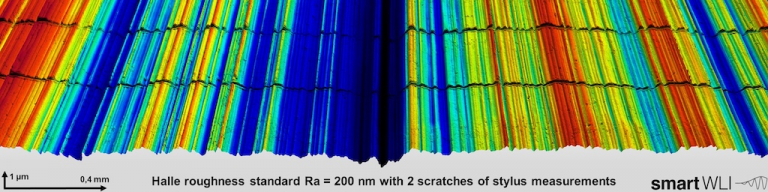

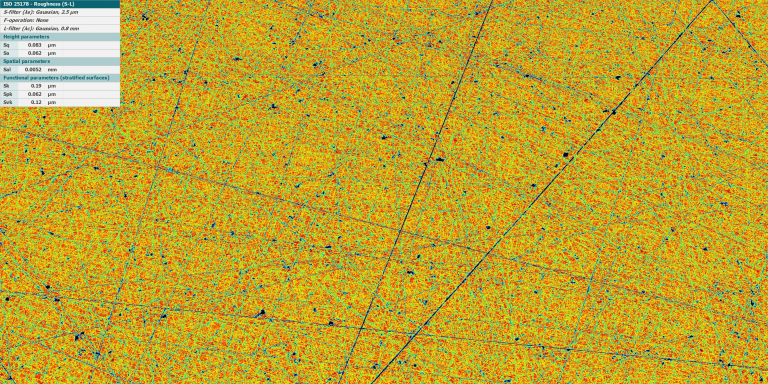

Optical systems allow for reference measurements with significantly higher resolution than tactile instruments.

System Selection

Choose a system with the required, not necessarily the maximum, resolution. This allows larger areas to be measured in reasonable time while reducing costs.

High-End Metrology from GBS

Unlock the full potential of the nimbus8 and firebolt8 – cutting-edge high-resolution WLI systems with 8-MP high-speed cameras for precise measurements in production, research, and quality control.

GBS metrology GmbH supports you with personalized consulting, free test measurements, and tailored solutions precisely aligned with your measurement requirements.

Benefit from our extensive experience and innovative sensor technology – from seamless process integration to optimized application in practice.

Download

Download the full report “Requirements for the Lateral Resolution of a Profilometer” and explore practical examples illustrating these relationships.

Don’t measure just anything. Measure what matters.

FAQ

The autocorrelation length (Ral) is a measure of the distance over which surface heights remain statistically similar.

In other words, it describes how far you can move along a surface before the height values become statistically independent from one another.

DLIM can be determined experimentally by measuring test structures with known, repeating patterns (e.g. grids or sinusoidal profiles).

By observing the point at which the measurement system still captures the shape correctly – and when it begins to “smooth” or distort the structures – the lateral period limit can be identified.

Yes. The relationship between Ral and DLIM helps identify the optimal profilometer for a given measurement task:

-

If DLIM < Ral, the profilometer can fully resolve the structure → optimal measurement quality.

-

If DLIM > Ral, the structure can no longer be correctly captured → loss of detail and distorted roughness values.

Therefore, DLIM is a key selection criterion for achieving precise and reproducible measurement results.