Our smartWLI

technology

Our 3D surface metrology technology is based on powerful white light interferometry and sets standards in non-contact optical metrology. Through continuous research and technological development, we offer systems that capture even the finest surface structures with the highest accuracy and in real time.

In this section, we present the key features of our smartWLI technology—from GPU-based data processing and exceptional height and lateral resolution to innovative functions such as the extended acceptance angle and automated quality control of the point cloud (AQC).

Learn how our technology overcomes the limitations of traditional interferometry and sets new standards for efficiency, precision, and user-friendliness in surface measurement technology.

Don’t measure just anything.

Measure what matters.

You can download a different number of files. Select one or more files to download.

The optical 3D sensors and profilometers of the smartWLI series are characterized by a very high measuring speed, resolution, acceptance angle – i.e. the ability to record highly inclined surface areas and, above all, the ability to carry out measure-ments with extremely little interference from outliers. In practical use, the sensors therefore offer decisive advantages over alternative solutions.

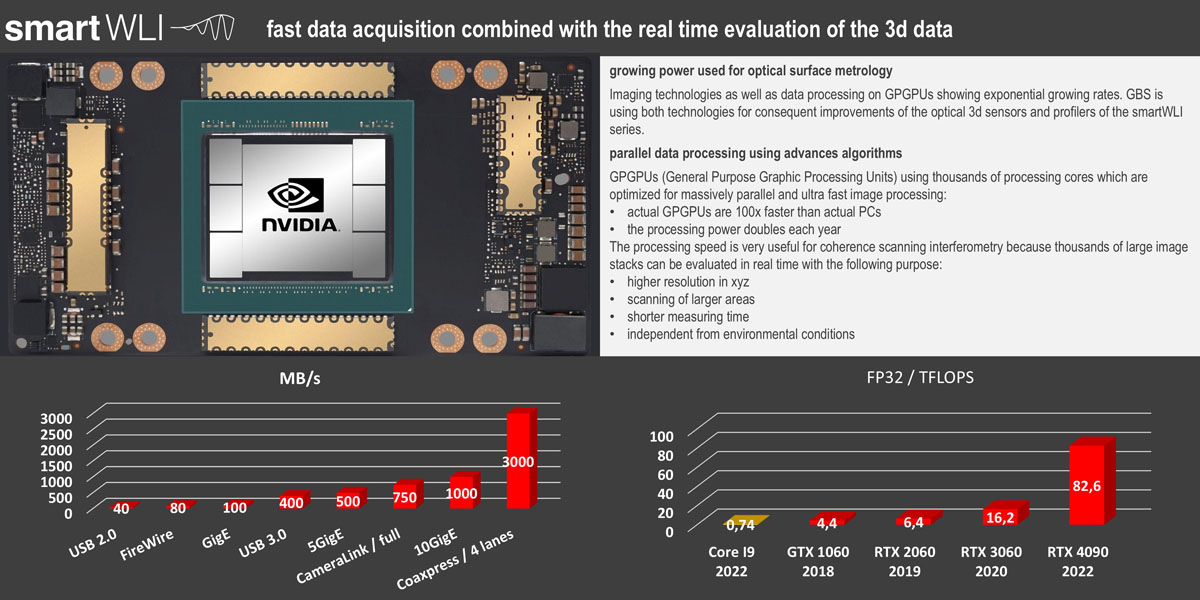

High-resolution, high-speed cameras are generally necessary to carry out high-resolution 3D measurements with optical 3D sensors in an acceptable measurement time. However, these also generate large amounts of image data that can only be saved with great effort. The Speedytec® technology offers the solution with data processing on current graphics cards with up to approx. 100 times the computing power of current CPUs. This enables the calculation of 3D data in real time without time-consuming storage of the image data.

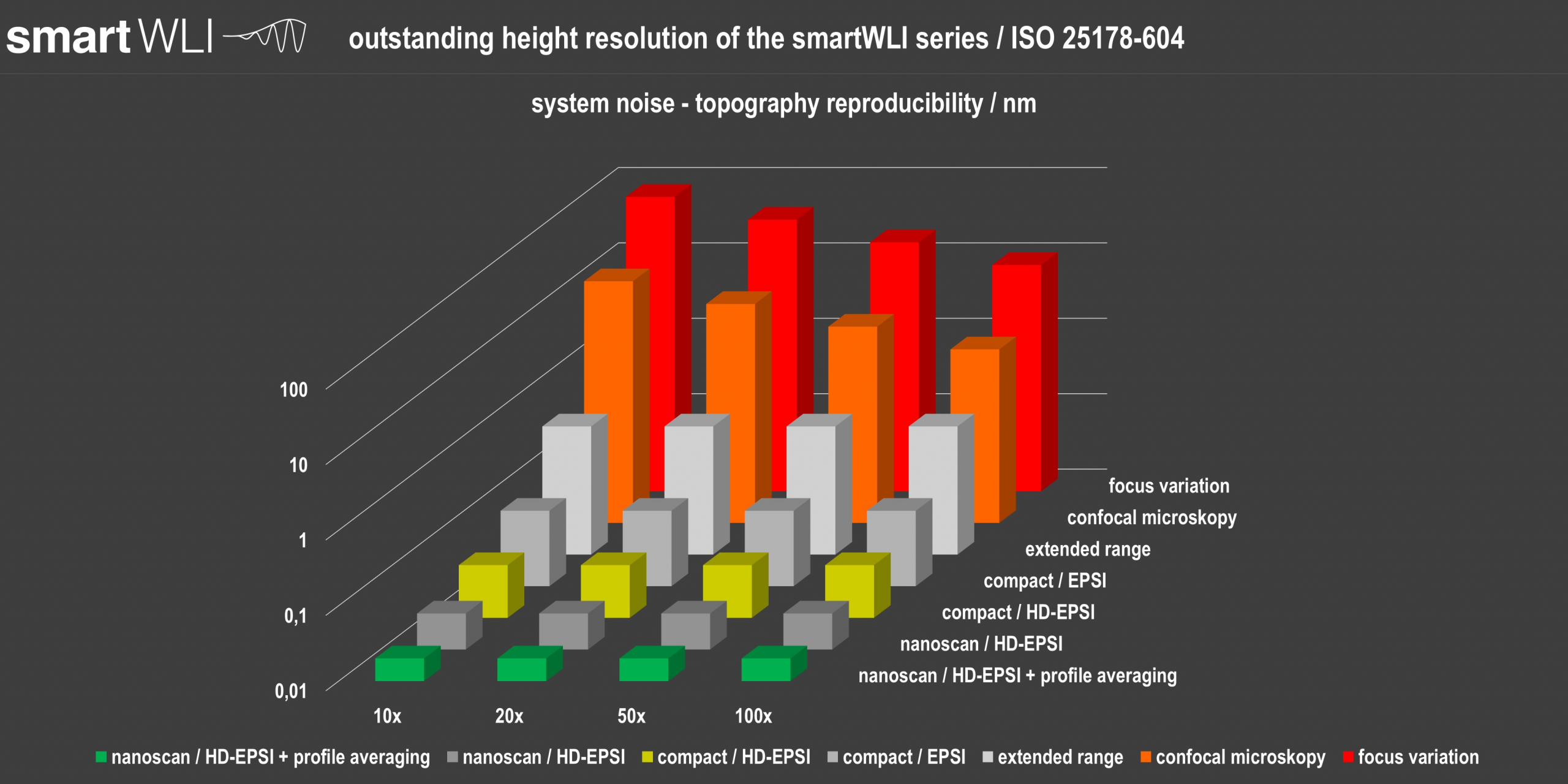

The height resolution is one of the most important parameters in surface measurement technology. Of all optical scanning measurement principles, coherence scanning (white-light) interferometry offers the highest height resolution which, in contrast to competing measurement methods, is independent of the objective magnification and measuring field size.

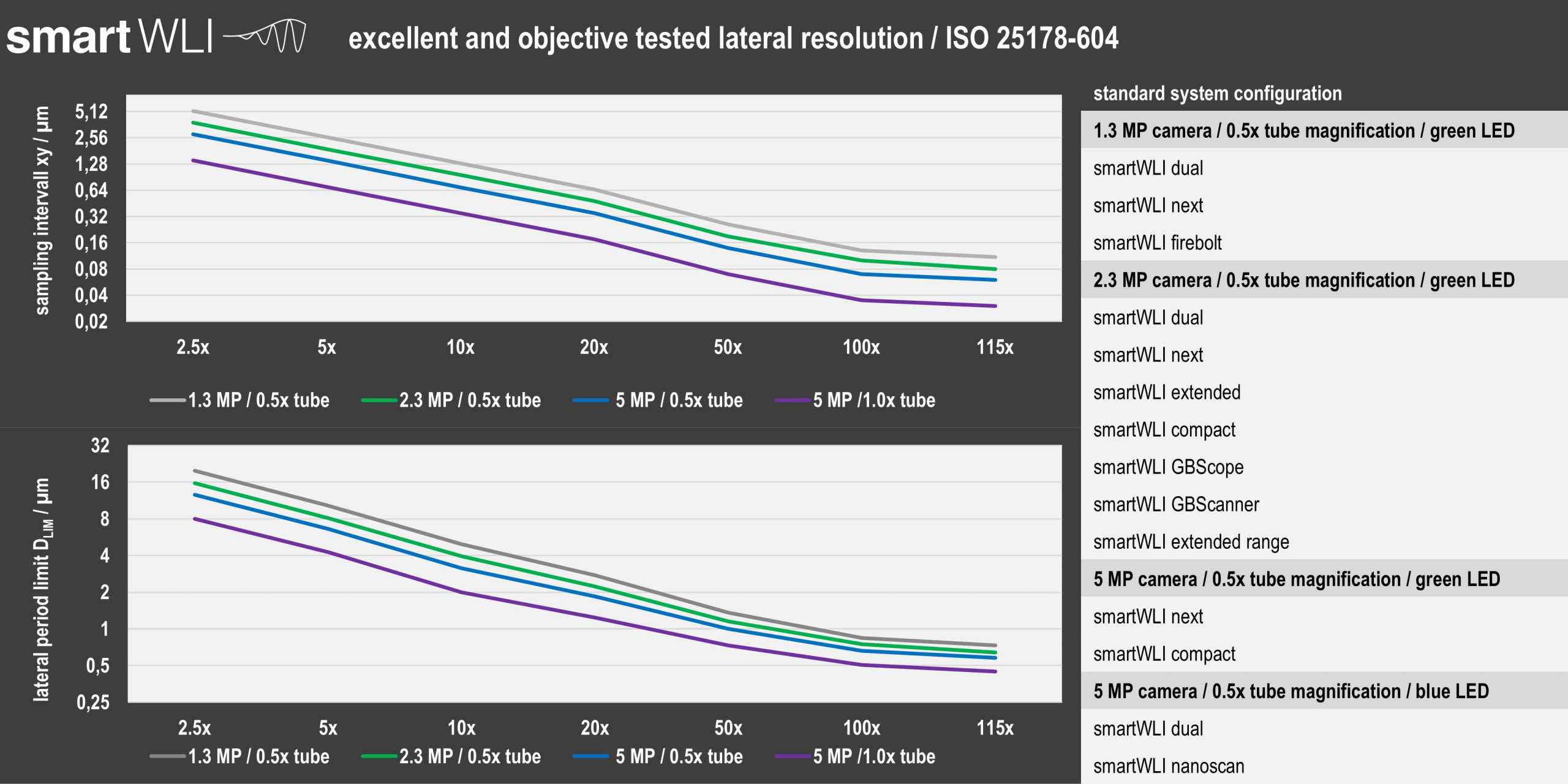

Coherence scanning (white-light) interferometry allows the calculation of height values without using information from neighboring points. By comparing interference contrast and focus, only image information with optimal sharpness is used. The lateral resolution is therefore not influenced by the focus position as in laser scan-ning and chromatic confocal sensors, not by the correlation matrix as in systems based on focus variation and not by the hole density of the Nipkow disk as used in confocal microscopes. This means that the lateral resolution is basically only limited by the optical resolution, although this can be exceeded in individual cases.

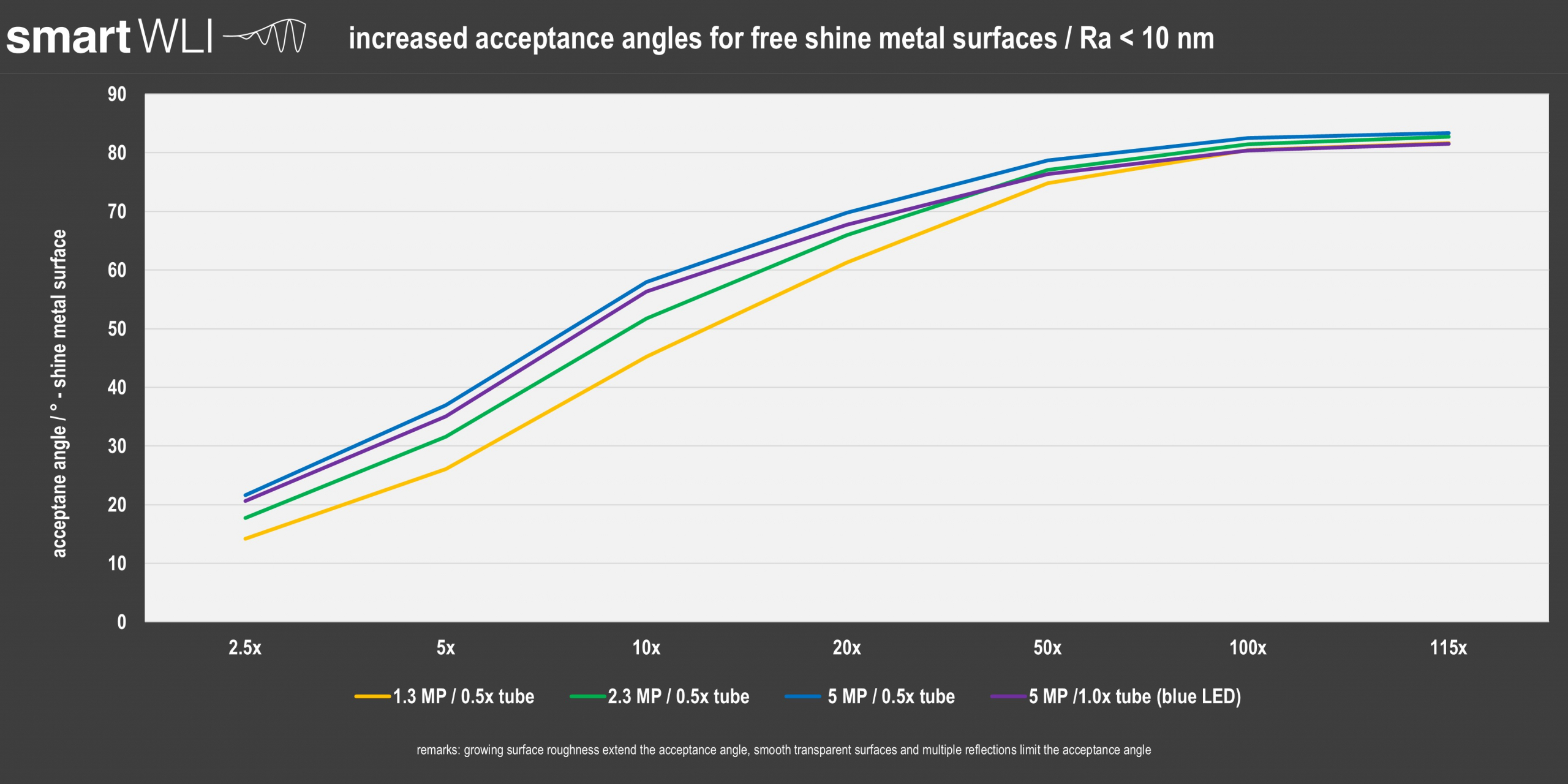

The steeper a surface area is inclined, the more difficult it is to correctly measure this area because less and less light is reflected back to the sensor and the signal can be affected by multiple reflections. Thanks to the computing power used, the smartWLI series allows the correct detection of small signals and the measurement of surfaces that are much more inclined than is possible with comparable systems.

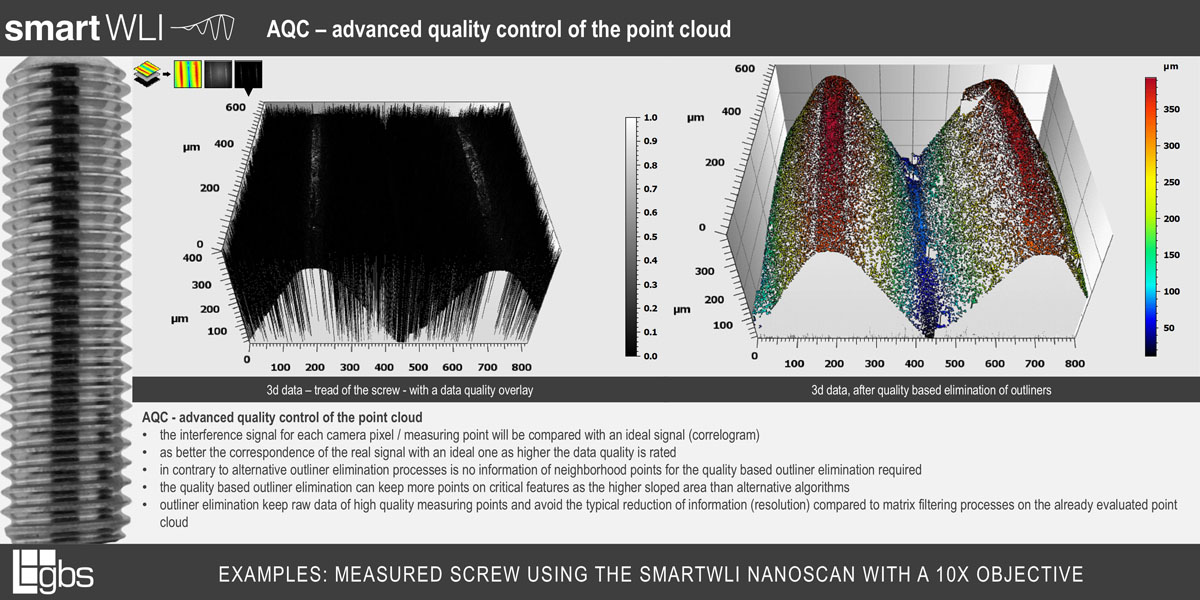

Especially for roughness measurements, it is important to be able to trust each individual measuring point. Even a small number of outliers can have a negative impact on the measurement result. The smartWLI series uses the possibility of comparing the real interference signal (correlogram) with an ideal one and calculating a quality value from the degree of agreement. Points with insufficient data quality can be eliminated directly. Losses in resolution, such as those associated with the usual use of matrix filters, are thus avoided.

Why GBS?

We measure, analyze, and visualize technical surfaces in 3D—from tool steel to semiconductor wafers. Precise. Comparable. Reproducible.

Years of market experience

industrial partners

Made in Germany

systems installed in the last 5 years