3D Metrology for the Automotive and Aerospace Industries

Precision, safety, and efficiency – three key requirements in the automotive and aerospace industries. Our 3D surface metrology supports manufacturers and suppliers in reliably achieving these goals.

From inspecting components with tight tolerances to analyzing complex geometries, our non-contact measurement technology provides high-resolution data for quality assurance, process control, and materials research.

GBS Metrology GmbH: Precise Surface Metrology Since 1997

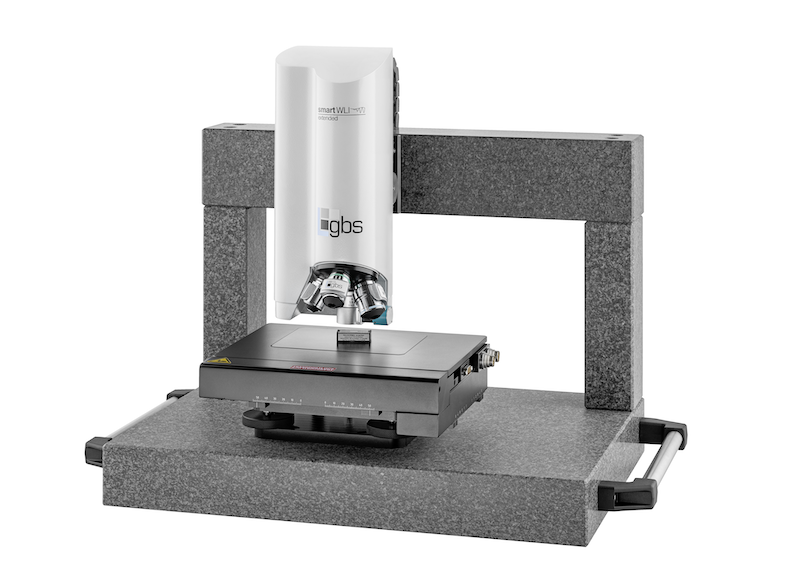

Since 1997, GBS Metrology GmbH has been developing, manufacturing, and distributing innovative solutions for the precise acquisition and evaluation of micro-geometries, surface structures, and roughness.

The product portfolio includes optical 3D sensors, 3D profilometers, portal measuring systems, and production-integrated measurement stations.

Thanks to powerful GPGPU-based image processing, the systems achieve extremely short measurement times and can be used both in the laboratory and directly in production — including inline applications.

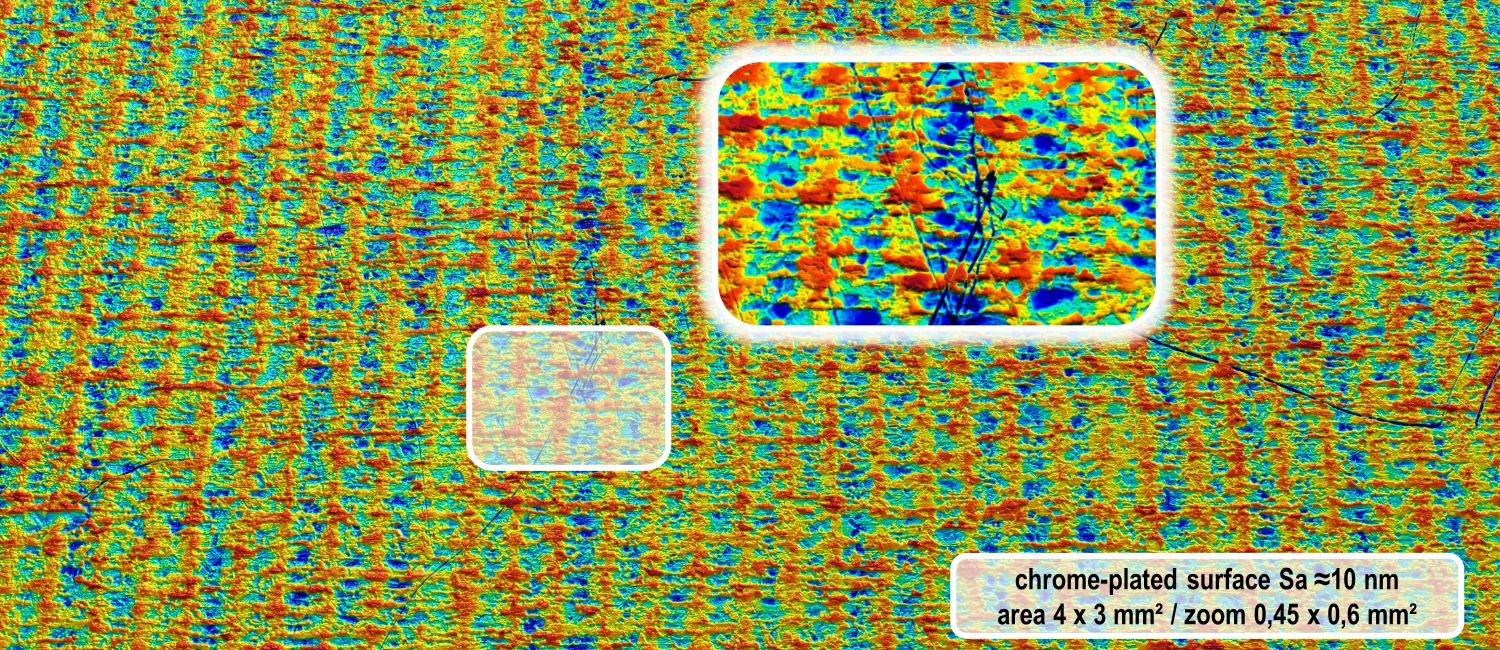

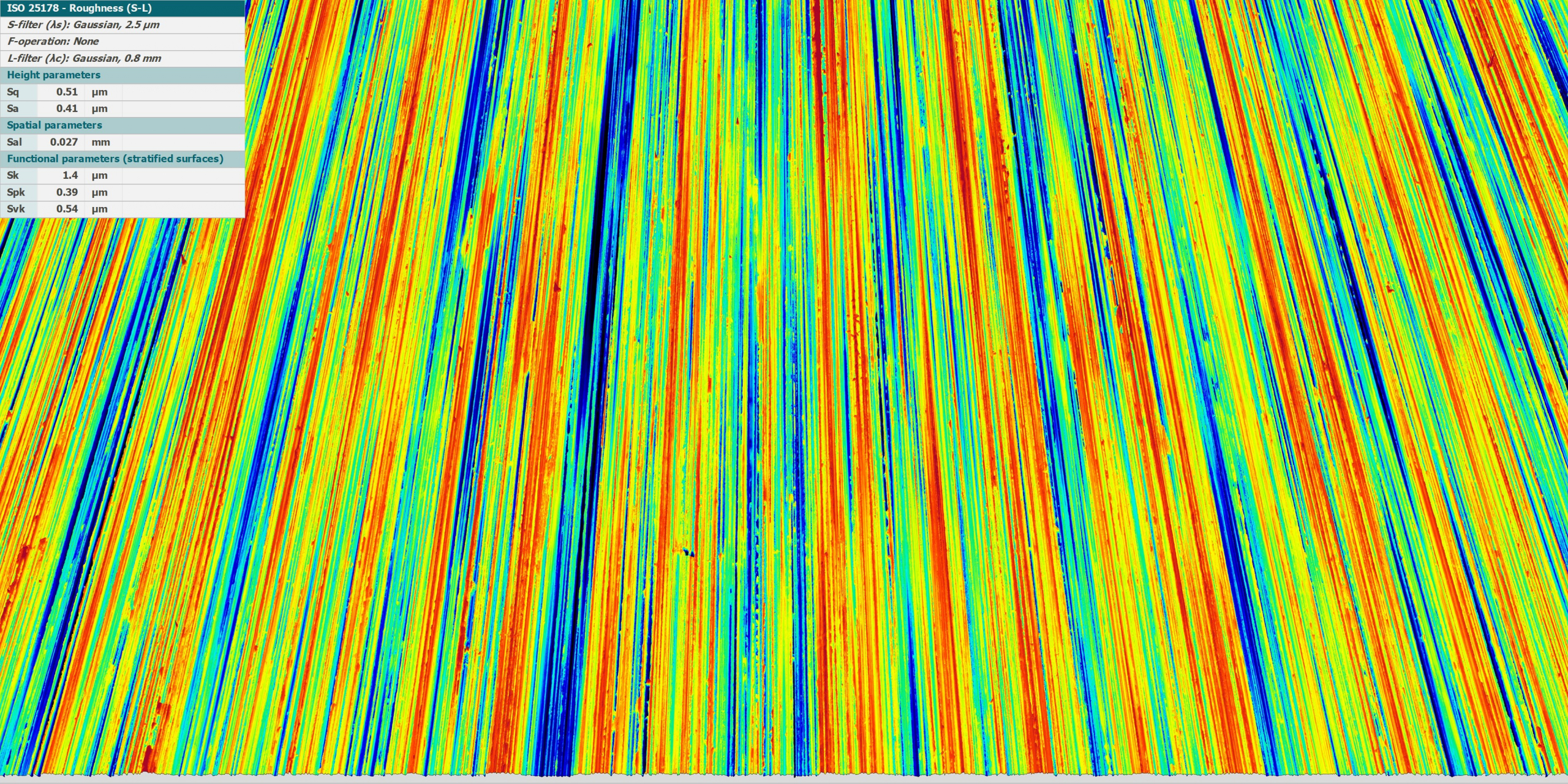

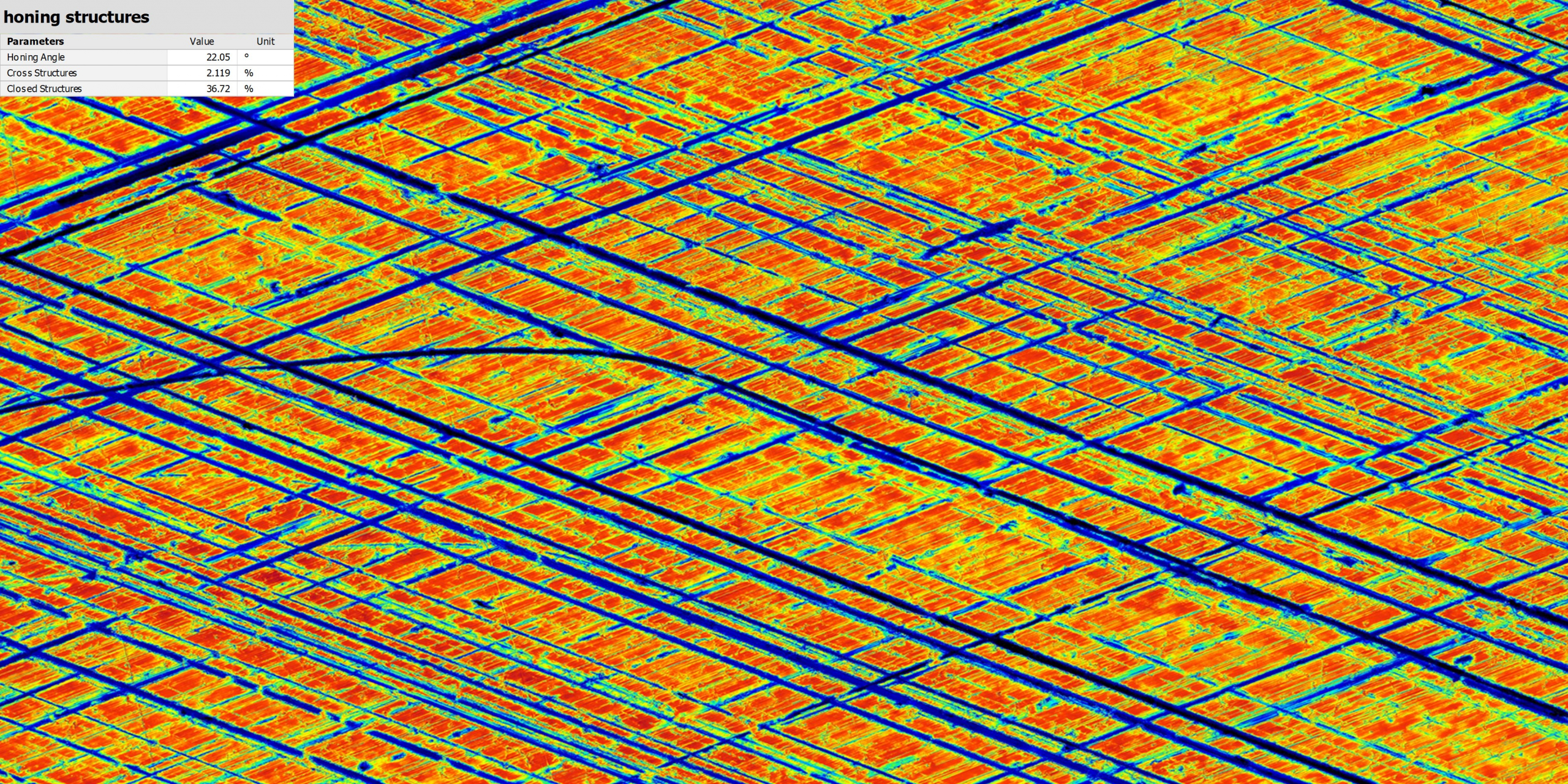

The white light interferometry measurement method enables high-resolution analysis of a wide variety of surfaces.

The smartWLI product line stands for 3D surface metrology at the micro- and nanometer scale.

Applications of 3D Surface Metrology in the Automotive and Aerospace Industries

Engine and Powertrain Components

Cylinder liners, pistons, and valves are inspected for shape accuracy, surface roughness, and wear.

3D surface metrology supports series production with fast, non-contact measurements, ensuring the functionality and durability of components.

Lightweight Materials and Structural Components

Aluminum, titanium, and fiber composite parts in car bodies or aircraft structures require precise surface quality control. The measurement systems capture micro-roughness, coating thickness, and bonding defects to optimally balance weight and strength.

Coatings and Functional Surfaces

Coated components such as brakes, bearings, or turbine blades benefit from the analysis of coating thickness, homogeneity, and adhesion.

The metrology detects deviations early and supports process monitoring.

Electronic Assemblies and Sensors

Contact surfaces, circuit traces, and housings in control units and sensors must be manufactured with high precision.

The metrology inspects topography, flatness, and transitions to ensure functionality and integration.

Prototype Development and Materials Research

In development projects for vehicles or aircraft, the surface topography of new materials, adhesives, and joining technologies is analyzed. The results directly contribute to the optimization of components and manufacturing processes.

Quality Assurance and Documentation

Every measurement provides traceable data for certifications, standards compliance, and approval processes in the automotive and aerospace industries.

Comprehensive documentation ensures safety and transparency throughout the supply chain.

Measurement Solutions for Precision and Innovation in Automotive & Aerospace

The automotive and aerospace industries demand metrology that reliably verifies the tightest manufacturing tolerances and complex surface structures.

GBS metrology’s 3D surface measurement technology is based on coherence scanning interferometry and GPGPU technology, enabling high-resolution, fast, and reproducible measurements.

The systems are flexibly usable in laboratories, production, and inline applications and can be easily integrated into process chains. In series production and development, the smartWLI systems support precise inspection of structural and functional surfaces, lightweight components, and coatings.

Defect patterns are reliably detected and documented, new materials thoroughly analyzed, and results fully traceable. Modular products and powerful software provide comprehensive and automated analyses.

Advantages of 3D Surface Metrology for Automotive & Aerospace

-

High measurement accuracy for complex and minute structures

-

Fast, non-contact inspection even in series production

-

Reproducible results and reliable traceability

-

Flexible integration into laboratory and production environments

-

Efficient detection and documentation of defect patterns

-

Support for development and optimization of new materials

-

Compatibility with common certification and quality standards

GBS Solutions for the Automotive and Aerospace Industries

GBS metrology offers modular 3D surface metrology solutions designed to meet the demands of the automotive and aerospace industries. The systems enable precise and rapid analysis of components, surfaces, and coatings—both in production and development. With powerful software and flexible integration, GBS delivers reliable measurement data for quality assurance, process optimization, and innovation.

Quality Assurance and Process Control in Production and Development

In mass production for the automotive and aerospace industries, the smartWLI systems support the inspection of components with complex geometries. Structural and functional surfaces, such as cylinder bores or cutting edges, are measured and evaluated without contact.

Lightweight components and coatings are inspected with high speed and accuracy. Defects such as cracks, scratches, or material inhomogeneities are detected and documented. In material development, new materials and surface technologies can be thoroughly characterized, with measurement results fully traceable.

3D surface measurement technology enables detailed analysis of new materials and documents all measurement results seamlessly. This allows development processes to be tracked precisely and compliance with quality standards to be verified at any time.

Customer Feedback

Measurement stations for rapid inspection of precision turned parts in the production environment

At the start of each shift in the precision turned parts production at Klumpp Präzisionswerk GmbH & Co. KG, the dimensional accuracy of the turning tools is checked. For this purpose, workpieces from ongoing production are handed over to the measurement lab to obtain approval for further manufacturing. However, in series production with multiple CNC lathes, the large number of measurements often leads to an overload of the lab.

GBS Metrology GmbH developed an automated measurement station. The station can be installed directly in the production environment, close to the turning machines. This allows operators to inspect their manufactured parts independently, without requiring prior metrology knowledge or extensive training.

After the installation of the measurement station from GBS Metrology, a rapid integration into the production process with high acceptance was observed. The relief of personnel in the measurement lab and the resulting acceleration of production release clearly increased the scope and efficiency of the manufacturing processes.

FAQ

GBS’s 3D surface metrology is highly versatile and particularly suited for the following components and applications:

-

Engine and drivetrain components

-

Lightweight materials and structural parts

-

Coatings and functional surfaces

-

Electronic assemblies and sensors

-

Prototype development and materials research

-

Quality assurance and documentation

The systems offer flexible integration in both laboratory and production environments. Thanks to SDKs and open interfaces, seamless connection to existing process chains is easily achievable.

Powered by advanced GPGPU image processing, results are available within seconds, enabling rapid process control and minimizing production downtime.