Precision Measurement for Components in the Optical Industry

In the optical industry, maximum precision is essential. Even the slightest deviations in shape or surface roughness can significantly impact the performance of optical systems. Our 3D surface metrology enables non-contact, high-resolution measurement of optical components – fast, reproducible, and non-destructive.

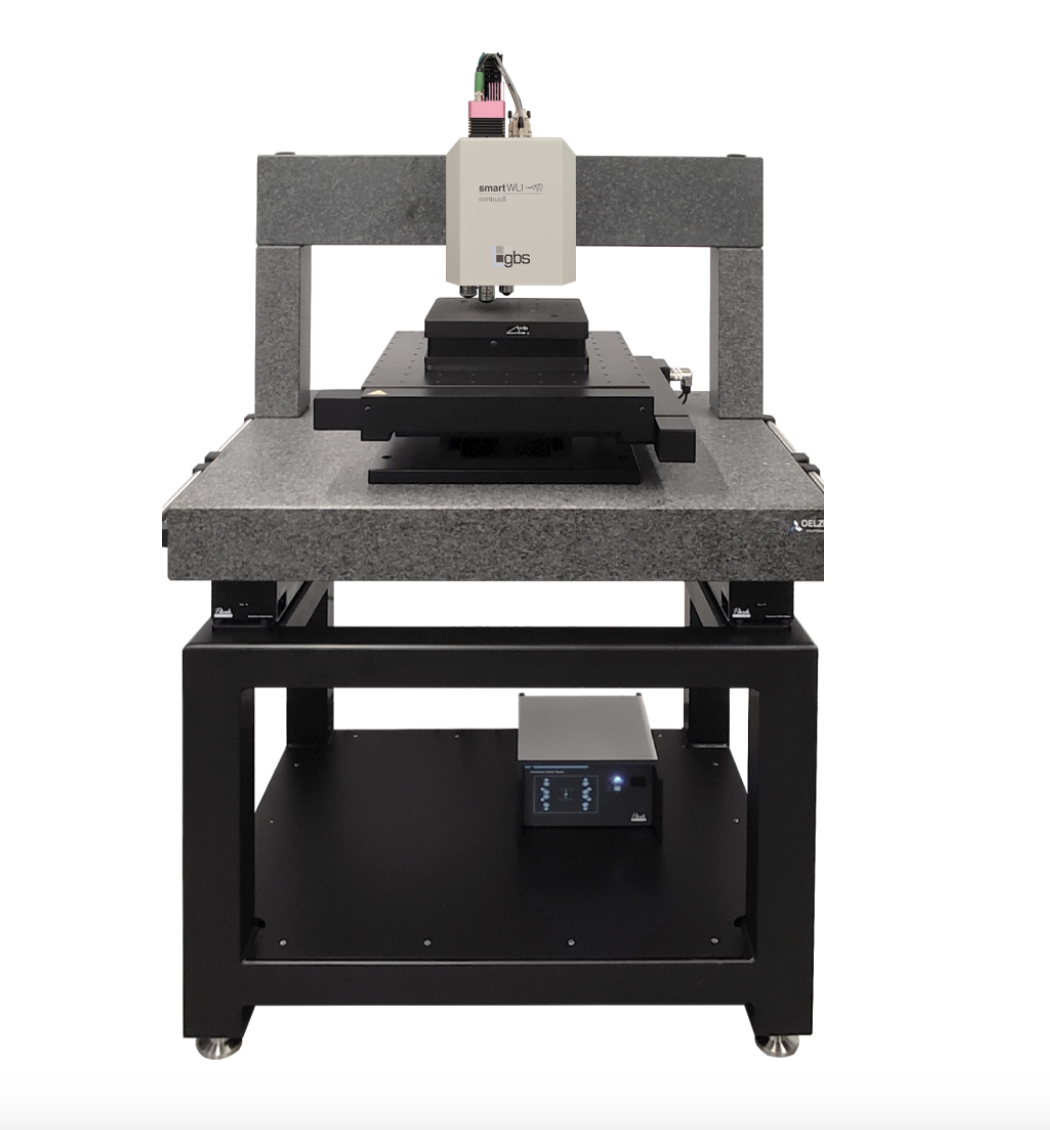

GBS – Efficient Measurement Systems and Software Solutions

Since 1997, GBS metrology GmbH has specialized in the development, production, and distribution of surface metrology systems.

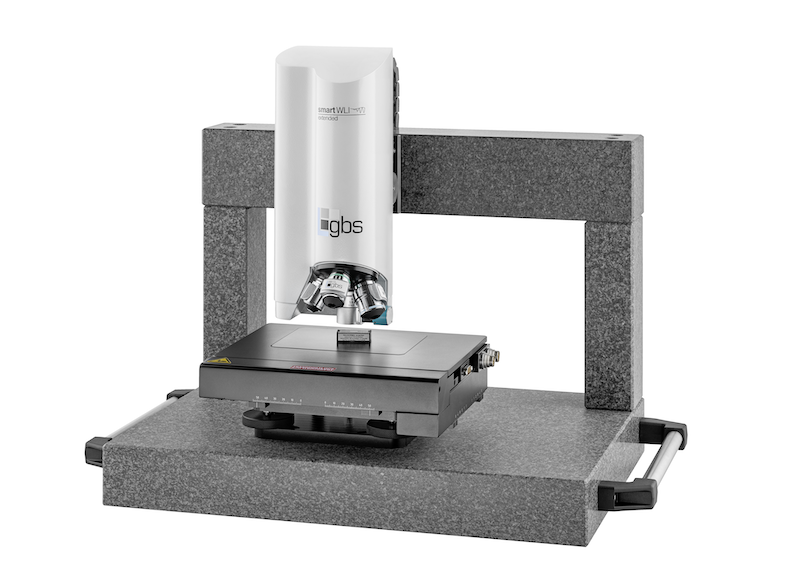

Our company offers optical 3D sensors, 3D profilometers, gantry-type measuring systems, and production-integrated measurement stations for the precise acquisition and evaluation of micro-geometries, surface structures, and roughness.

Thanks to massively parallel image processing on GPGPUs, extremely short measurement times are possible – making our systems suitable for use not only in the laboratory but also directly in production environments or inline.

The use of white-light interferometry enables ultra high-resolution measurements, especially with our smartWLI product line designed for micro and nano structures.

Components and Fields of Application in the Optics Industry

Lens Manufacturing

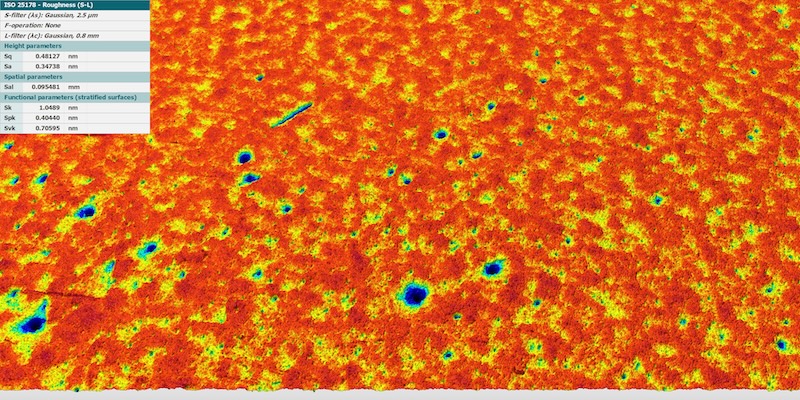

Spherical and aspherical lenses are used in imaging systems, cameras, and optical sensors. 3D surface metrology is used to inspect their shape as well as nano- and micro-scale roughness to ensure optimal optical performance.

Mirror Manufacturing

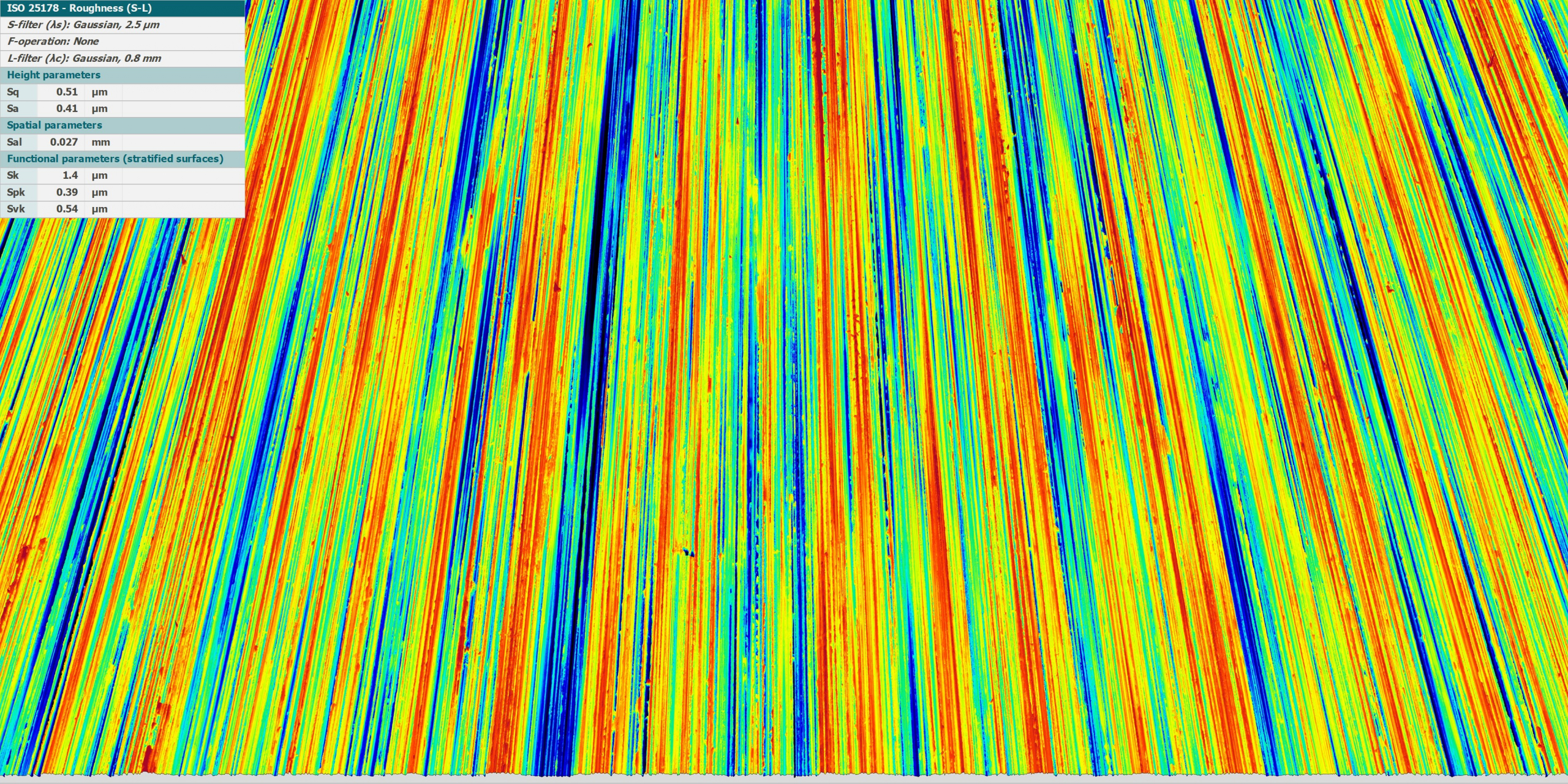

Precision mirrors, such as those used in laser technology, require exact control of surface topography and flatness. The measurement systems detect shape deviations and assess reflective properties.

Freeform Optics

Freeform surfaces are used in AR/VR systems, sensor technology, and lighting applications. Metrology systems enable the non-destructive inspection of complex geometries and surface structures.

Diffraktive optische Elemente

Diffractive structures are used in spectroscopy, image processing, and metrology. The measurement systems verify the accuracy of microstructures, as well as step heights and periodicity.

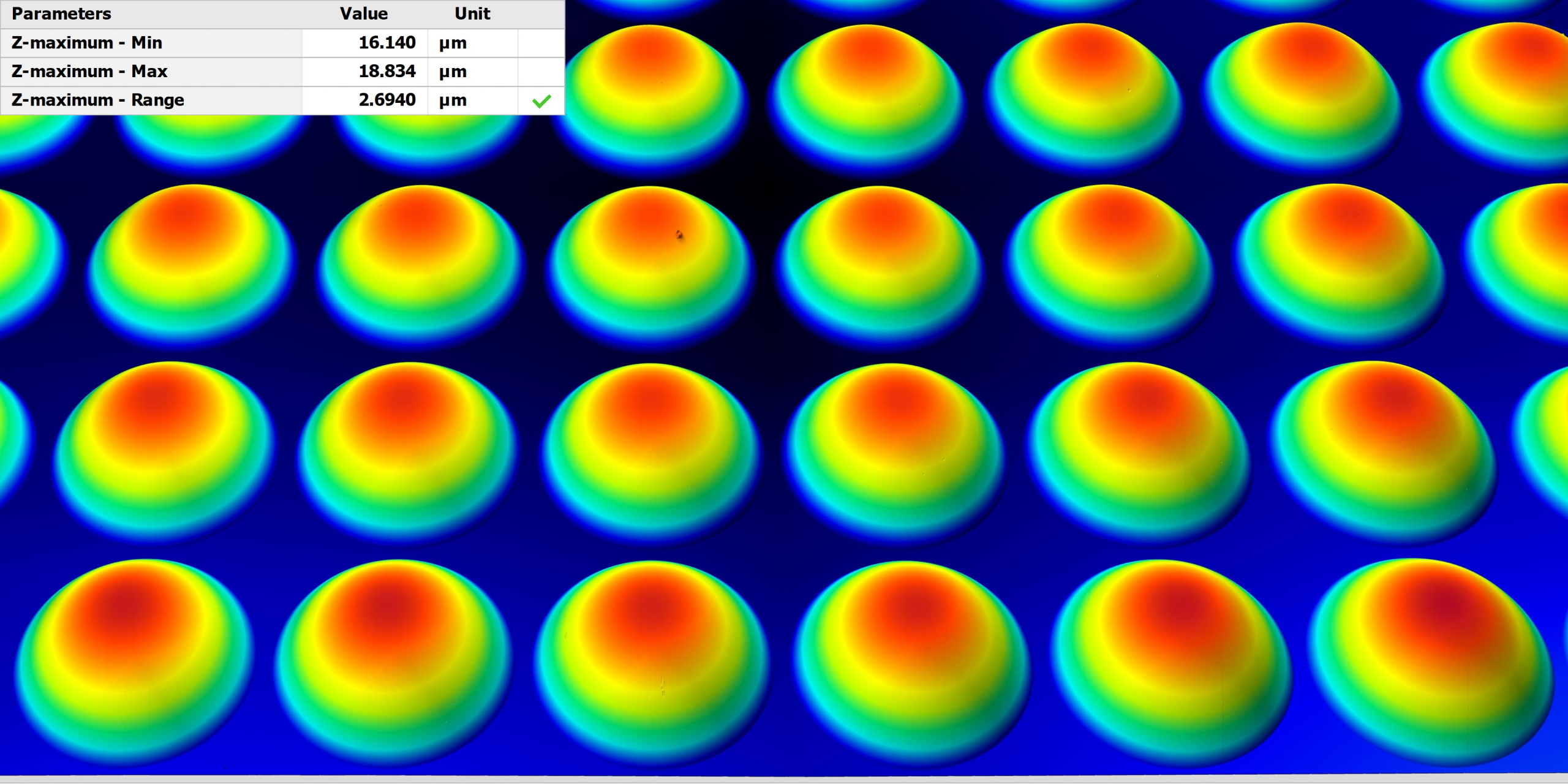

Microlens Arrays

Microlens arrays are crucial for the miniaturization of optical systems. 3D surface metrology measures the topography and uniformity of individual lenses within the array.

Optical Glasses and Filters

Optical filters and glasses are used in measurement and inspection systems. The measurement systems inspect surface roughness, coating thickness, and planarity.

Components in Semiconductor and Medical Technology

Optical components such as wafers, prisms, and glass elements are used in semiconductor and medical technology. 3D metrology provides data for quality control and process monitoring.

3D Surface Metrology as a Solution for Optics

The measurement method used is based on non-contact and non-destructive acquisition of surface data. The measurement systems achieve sub-nanometer resolution and deliver reproducible results in the shortest possible time.

Integrating 3D surface metrology into production lines or laboratories enables efficient control of large quantities. The measurement data can be used directly to inspect topography, form accuracy, and roughness. Due to the high flexibility of the technology, it can be applied to various optical components without modifications.

Advantages of 3D Surface Metrology for Optics

-

Non-contact and non-destructive measurement of optical components

-

Sub-nanometer resolution for shape, roughness, and topography

-

Fast measurement times through parallel image processing

-

Reproducible and traceable measurement results

-

Flexible integration into laboratories, manufacturing, and inline applications

-

Direct quality control and process monitoring

Precise 3D Metrology for Optical Components by GBS

GBS Metrology offers high-resolution 3D surface metrology for precise and non-destructive inspection of optical components at all manufacturing stages. Systems such as the smartWLI sensors enable fast and reliable detection of topography, form deviations, and roughness. The solutions are highly flexible and allow efficient quality control of lenses, mirrors, freeform optics, and other components in the optics industry.

Integration of Metrology into Production Processes

The smartWLI systems from GBS are designed for the measurement of optical components. With fast data access and various objective lens options, they offer a wide range of applications.

The systems are suitable for use both in manufacturing and laboratory environments. The MountainsMap® software enables evaluation and analysis of measurement data according to international standards. Automated test reports ensure comprehensive documentation.

The integration of 3D surface metrology takes place at all manufacturing stages—from development through series production to final inspection. The technology can be used both inline and atline, supporting the automation of inspection processes.

Interfaces to existing production systems and customization to individual requirements ensure seamless integration into the manufacturing process of optical components.

Customer Feedback

Measurement stations for rapid inspection of precision turned parts in the production environment

At the start of each shift in the precision turned parts production at Klumpp Präzisionswerk GmbH & Co. KG, the dimensional accuracy of the turning tools is checked. For this purpose, workpieces from ongoing production are handed over to the measurement lab to obtain approval for further manufacturing. However, in series production with multiple CNC lathes, the large number of measurements often leads to an overload of the lab.

GBS Metrology GmbH developed an automated measurement station. The station can be installed directly in the production environment, close to the turning machines. This allows operators to inspect their manufactured parts independently, without requiring prior metrology knowledge or extensive training.

After the installation of the measurement station from GBS Metrology, a rapid integration into the production process with high acceptance was observed. The relief of personnel in the measurement lab and the resulting acceleration of production release clearly increased the scope and efficiency of the manufacturing processes.

FAQ

The metrology is suitable for lenses, mirrors, freeform optics, microlens arrays, and diffractive elements. It precisely and non-destructively measures shape, topography, and roughness.

The systems are designed for both inline and atline applications and can be integrated at all manufacturing stages. Interfaces and automation options ensure seamless integration.

3D surface metrology is contactless, fast, and provides submicrometer resolution. It is ideal for sensitive optical components and reduces measurement times as well as the risk of damage.