Grinding tools

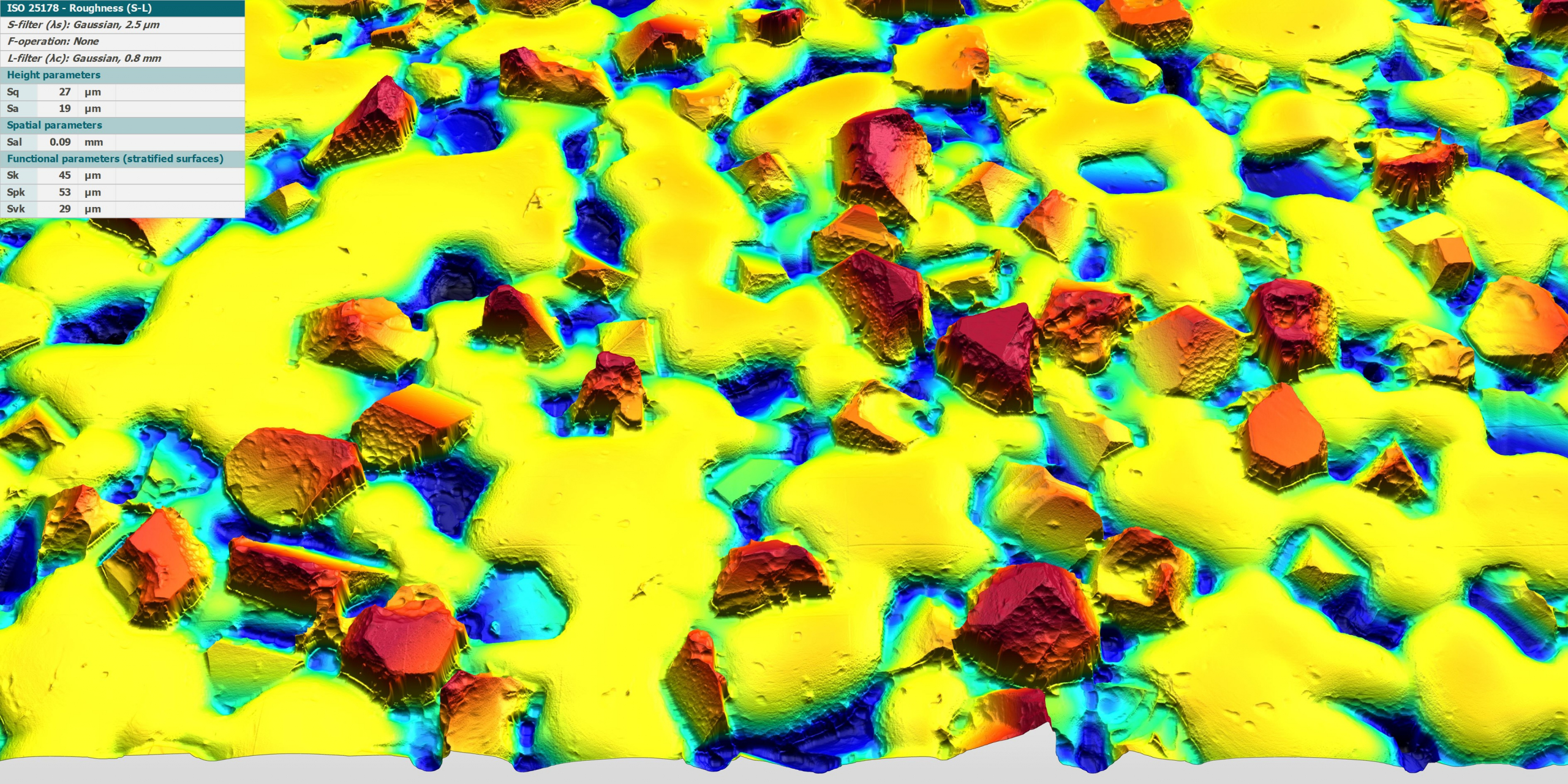

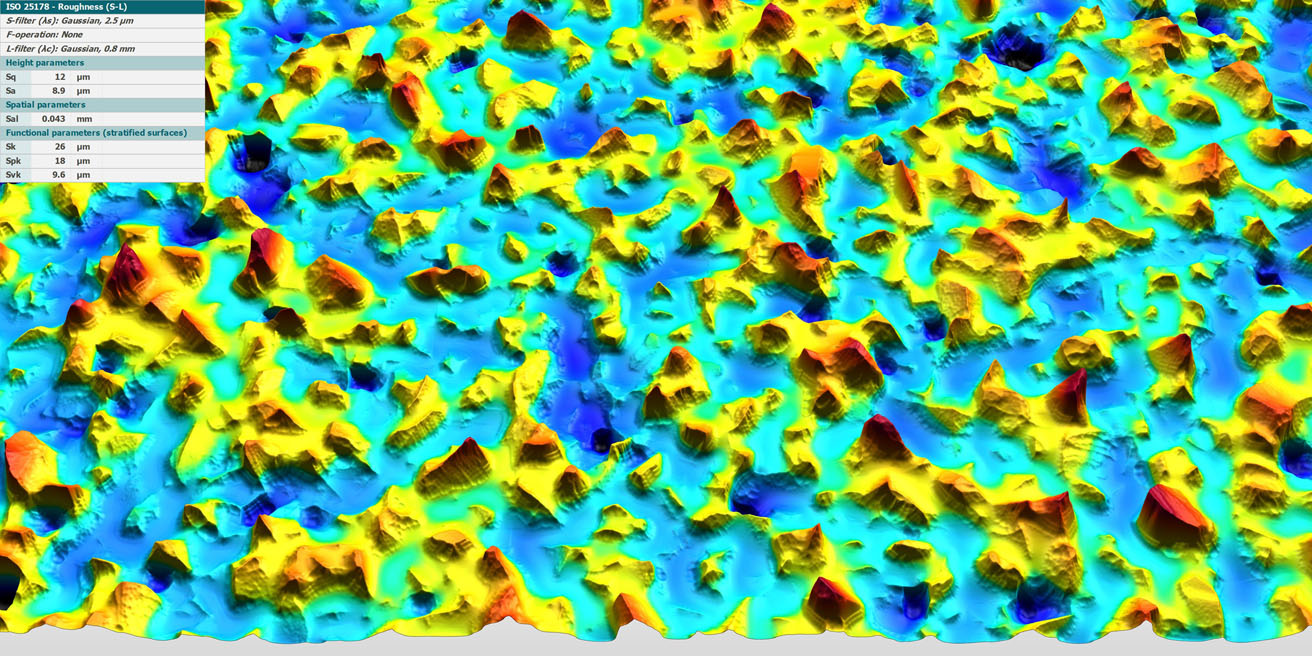

Grinding tools and in particular the surfaces of diamond tools place high demands on the optical measuring device and the evaluation of weak reflections from trans-parent, sharply sloping, and smooth edges, but not necessarily on the height resolution. Typically, systems without piezo with 20x and 50x lenses are used.

Don’t measure just anything. Measure what matters.

You can download a different number of files. Select one or more files to download.

The evaluation of the surfaces of diamond tools is only possible to a limited extent using roughness parameters. For this reason, special evaluation options are used in which the abrasive grains are recorded and evaluated individually. This is followed by statistical evaluations in which, for example, the grain density, breakouts, or the protrusion above the embedded material can be evaluated.

The local assessment of the surface structure is often not sufficient as there can be significant differences on larger areas. A high measuring speed is an advantage to be able to measure many positions in an acceptable time.